Advertisements

why repair strip easily be scraped from belt cleaner when conveyor belt repair

| Price: | US$ 1 / Roll |

|---|---|

| Minimum Order: | 1 |

| Payment Terms: | TT |

| Port of Export: | Shanghai |

Product Details

| Model No.: | Brand Name: | Ramimtech |

|---|

| Certification: | ISO |

|---|---|

| Specification: |

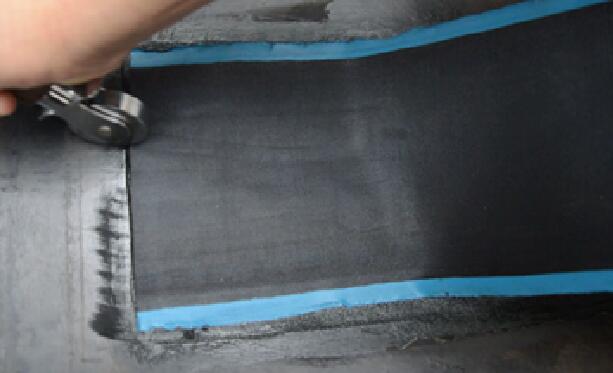

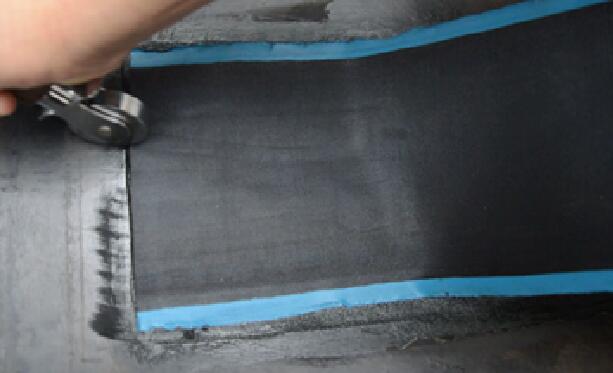

The sanding depth of repair part that should be bigger than the thickness of repair strip.

Because the little space between belt cleaner and conveyor belt, so the sanding depth should be bigger than the thickness of repair strip.(such as 150 reinforced repair strip, the thickest part is 4.6mm, so the sanding depth should be 4.6mm), while bonding, we should choose embedded way that can avoid the bonding part be scraped by belt cleaner. |

Packaging & Delivery

| Packaging: | carton |

|---|---|

| Delivery/Lead Time: | 5 days |

| Production Capacity: | 10000 |

Product Description

why repair strip easily be scraped from belt cleaner when conveyor belt repair

After repair strip bonds on repair strip, and we start the conveyor, at this time, repair strip be scraped from belt cleaner, then some workers will complain the products quality is not good, because the belt cleaner works well at before.

In fact not, the situation contains a lot, we can not say the repair strip and the glue doesn’t have good quality, we should find reasons from all aspects.

Traditional glue is flammable, and not have good bonding strength and have limitations.

At present, we repair conveyor belt usually applies traditional universal glue, at before this kind glue is truly good, it can bonds all kinds of products, but in pace with the change of traditional technologies, the material of conveyor belt is changed from rubber to compound rubber, once it contains the special material such as PVC material, traditional universal glue will be not available.

New model cold vulcanization glue SK313 is non-flammable, high bonding strength and low material requirement.

Cold vulcanization glue SK313 is safe and non-flammable, which suitable for ground and underground operation, whose excellent bonding strength far more exceed Germany DIN industrial standard, which have the same grade with traditional hot vulcanization bonding strength, during the cold seamless bonding, whose bonding strength that can exceed the hot vulcanization bonding strength, while we do emergency repair, no need for any big equipment, once repair that can use it immediately.

The sanding depth of repair part that should be bigger than the thickness of repair strip.

Because the little space between belt cleaner and conveyor belt, so the sanding depth should be bigger than the thickness of repair strip.(such as 150 reinforced repair strip, the thickest part is 4.6mm, so the sanding depth should be 4.6mm), while bonding, we should choose embedded way that can avoid the bonding part be scraped by belt cleaner.

Except above notice, one should obey the conveyor belt repair technology and standard, such as repair part sanding, keep sanding part dry and clean, that can keep the whole process goes smoothly.

|

SUPPLIER PROFILE

|

|||

|---|---|---|---|

| Company: | HENAN YINMEITE MACHINERY CO.,LTD | ||

| City/State | Zhengzhou, Henan | Country: |

China

|

| Business Type: | Export - Manufacturer / Trading Company | Established: | 2008 |

| Member Since: | 2013 | Contact Person | Alick Gao |

SUPPLIER PROFILE

City/State/Country -

Zhengzhou, Henan

China

Business Type -

Export - Manufacturer / Trading Company

Established -

2008

Member Since -

2013

Contact Person -

Alick Gao