Advertisements

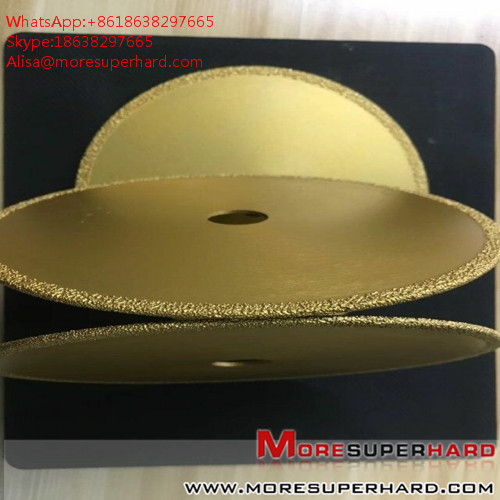

Vacuum brazing diamond saw blade processing various natural stones [email protected]

| Price: | US$ 50 |

|---|---|

| Minimum Order: | 1 piece |

| Payment Terms: | T/T, Western Union, MoneyGram |

| Port of Export: | Shanghai |

Product Details

| Model No.: | Brand Name: | Moresuperhard |

|---|

| Certification: | ISO9001 |

|---|---|

| Specification: | Our vacuum brazed saw blades have continuous type and segment type. They are used for cutting Marble, cast iron, Ceramics tiles, hard composite materials such as concrete with rebar, Metal processing, Fiber Glass and PVC pipe, etc |

Packaging & Delivery

| Packaging: | carton box with foam box (Gift package is available) |

|---|---|

| Delivery/Lead Time: | 7-10 work days |

| Production Capacity: | 1000 piece every week |

Product Description

Details

Our vacuum brazed saw blades have continuous type and segment type. They are used for cutting Marble, cast iron, Ceramics tiles, hard composite materials such as concrete with rebar, Metal processing, Fiber Glass and PVC pipe, etc

Feature

1:Name:Vacuum Brazed Diamond Saw Blades

3:Material: Diamond

4:Application Industry: Jewelry, Automobile, Aerospace, Oil drilling, Coal mining, Metal processing

5:Certification: ISO 9001:2008

6:Diamond grit: #100, #150, #200, #300, #400, or upon your request

7:Type: Continuous And Segment

Product Feature introduction

1.high grinding efficiency

2.long work-life

3.less heat and jam generate in grinding

Advantages Of Vacuum Brazed Diamond Saw Blades:

1:Single Layer Of Fully Exposed Diamond Fused With Nickel At High Temperatures And Sharp Cutting

2:Small Cutting Gap And Less Chipping

3:Up To 40 Times Longer Life Time Than Resin Grinding Disc. The Efficiency Is Improved By 100% For Cutting FRP Slab

4:Higher Quality Process Than Sintered Or Laser Welded Diamond Wheel. The Efficiency Is Improved By 35% For Cutting Marble Slab

5:No Pollution, Low Noise ,Never Need Dressing

Specifications of vacuum brazed diamond saw blades:

Model:vacuum brazed diamond saw blade

D(Mm) H(Mm) T(Mm)

100 22.23 1.2

115 22.23 1.2

125 22.23 1.2

150 22.23,25.4 1.2,2.4

180 22.23,25.4 1.6

230 22.23,25.4 1.8

350 25.40,32 2

400 25.40,32 2.2,2.6

Grain Size: Rough 25/30, 30/35, 35/40, Finish 50/60

Others Size And Grit Can Be Customized According To Customers' Requirement.

What is vacuum brazing?

Vacuum brazing refers to the workpiece heating in the vacuum chamber, which is mainly used for welding products with high quality and easily oxidized materials. The vacuum brazing furnace consists of pressure vessels with cylindrical side walls and doors, and the size and location of the doors are designed to seal one end of the cylindrical side walls. The workpiece handling system is mounted on the pressure vessel door to support the workpiece for heat treatment or brazing. The workpiece processing system includes a device for turning the workpiece during processing. The vacuum system can be connected to the workpiece so that the pressure inside the workpiece is lower than atmospheric pressure during the brazing process.

Advantages of vacuum brazing:

1. Vacuum brazing, without using solder, significantly improves the corrosion resistance of products, eliminates various pollution and pollution-free treatment equipment costs, and has good production safety conditions.

2. Vacuum brazing not only saves a lot of expensive metal solder, but also does not require complicated flux cleaning process, which reduces production cost.

3. The vacuum brazing solder has good wettability and fluidity, and can be used to weld more complicated and narrow channel devices.

4. Compared with other methods, the internal structure and clamping device of the furnace have a long life, which can reduce the maintenance cost of the furnace.

5. There are many materials suitable for vacuum brazing, such as aluminum, aluminum alloy, copper alloy, stainless steel, alloy steel, low carbon steel, titanium, nickel, Inconei, etc., which can be soldered in vacuum furnace. The designer determines the materials required according to the use of brazing devices, among which aluminum and aluminum alloy are most widely used.

Why choose our grinding wheel

Our product’s advantages:

1.High grinding efficiency

2.Wonderful edge quality

3.Long service life

4.High polishing efficiency

5.Large Exports

6.Considerable after-sell service

7.Amazing performance

8.Various types and sizes available

9.Direct Factory Manufacturer

10.Backing/substrate material: Aluminum

11.Abrasive layer: diamond

12.Bond: vitrified

13.Excellent cutting edges

14.Reduced cycle times

15.Custom Engineered

If you have any questions, please contact us

|

SUPPLIER PROFILE

|

|||

|---|---|---|---|

| Company: | Henan More Super Hard Products Co.,Ltd | ||

| City/State | Zhengzhou, Henan | Country: |

China

|

| Business Type: | Export - Manufacturer / Trading Company | Established: | 2014 |

| Member Since: | 2018 | Contact Person | 'Alisa Zhang' |

SUPPLIER PROFILE

City/State/Country -

Zhengzhou, Henan

China

Business Type -

Export - Manufacturer / Trading Company

Established -

2014

Member Since -

2018

Contact Person -

'Alisa Zhang'