Advertisements

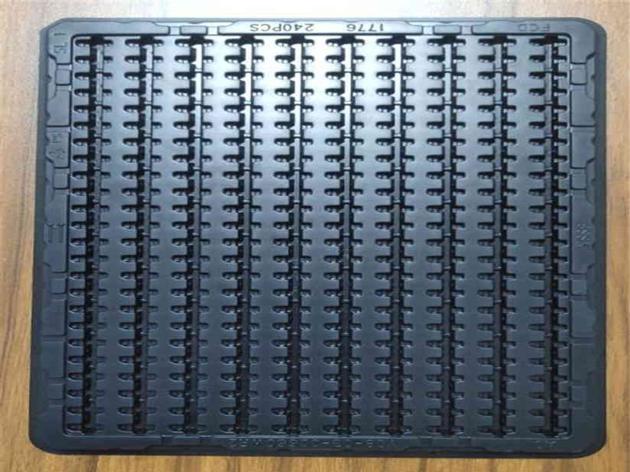

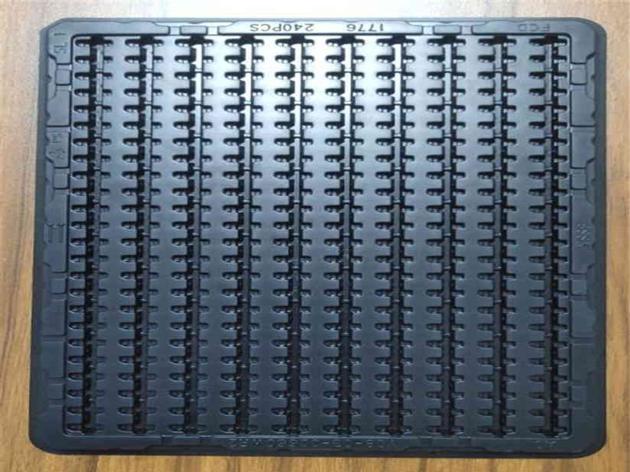

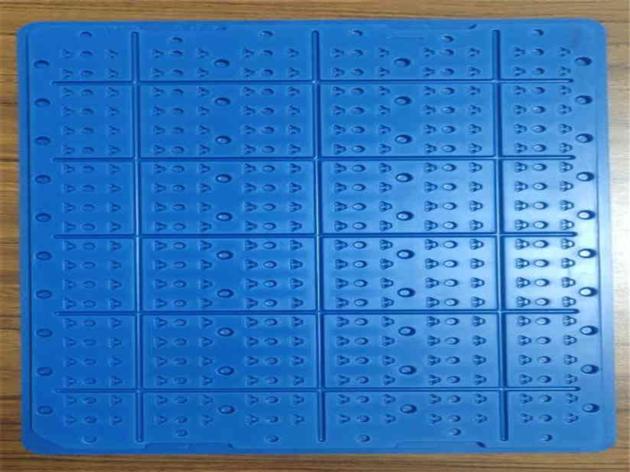

Vacuum Formed Trays

| Price: | US$ 0.1 |

|---|---|

| Minimum Order: | 10000 |

| Payment Terms: | t/t,l/c |

| Port of Export: | Shenzhen |

Product Details

| Model No.: | Brand Name: |

|---|

| Certification: | ROHS, ISO14001 |

|---|---|

| Specification: |

Name: Anti Static Plastic Tray

Color: Black Material: PS, AntiStatic Thickness: 0.8mm Certificates: RoHs, ISO14001 Payment Term: T/T Capacity: 100000pcs/week MOQ: 5000 pieces Sample Time: 5 days including tooling making Lead Time: 5-10 days after placing an order Packaging Details: Cartons 540*420*320MM OR As customers’ requirement Country of origin: China HS Code: 3923900000 |

Packaging & Delivery

| Packaging: | cartons |

|---|---|

| Delivery/Lead Time: | 15days |

| Production Capacity: | Shenzhen |

Product Description

Vacuum Formed Trays are commonly used for packaging applications due to its lower cost tooling, ability to run thin material, and large number of design features.

Thermoforming is made up of several similar processes. These include vacuum forming, pressure forming, and twin sheet forming. They all have applications with plastic packaging. Vacuum forming is used for more basic trays and is the least expensive option. Pressure forming adds pressure to the part pressing the plastic against the mold. Pressure forming is better for high detail, close tolerances, and small cavities. Twin sheet forming essentially welds two sheets of plastic together allowing for hollow parts or reinforced parts. Twin sheet forming is used for skids, trays with fork truck access, or for trays requiring two surfaces.

ADVANTAGES OF VACUUM FORMED TRAY PACKAGING

1. Low part cost and cost per component. Trays are also low in weight reducing shipping costs.

2. can streamline the packaging process saving significant time while properly protecting parts.

3. Minimises movement (and therefore damage) during handling

4. Can be tailored to your product / component(s) for optimum fit

5. Large number of material options including ESD materials and antistatic materials.

6. Thin material / nesting for saving space when not in use

7. Trays can be made to a specific even number like 50 or 100 cavities per tray facilitating counting.

8. Ideal for high volume requirements, and protecting high value items

|

SUPPLIER PROFILE

|

|||

|---|---|---|---|

| Company: | Shenzhen Sewate Technology Co., Ltd. | ||

| City/State | Shenzhen, Guangdong | Country: |

China

|

| Business Type: | Export - Manufacturer / Trading Company | Established: | 2003 |

| Member Since: | 2019 | Contact Person | james tong |

SUPPLIER PROFILE

City/State/Country -

Shenzhen, Guangdong

China

Business Type -

Export - Manufacturer / Trading Company

Established -

2003

Member Since -

2019

Contact Person -

james tong