Advertisements

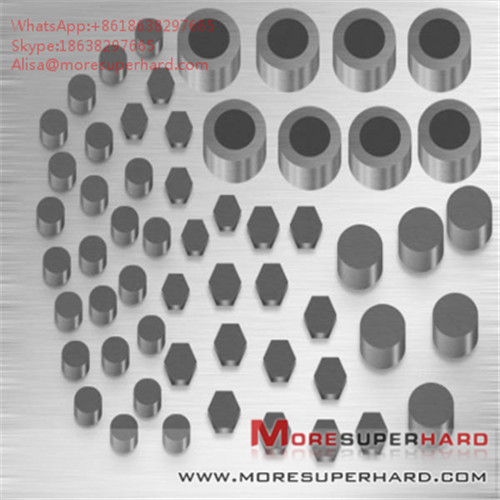

Tungsten Carbide Supported Diamond Die Blanks used to wire drawing [email protected]

| Price: | US$ 50 / Piece |

|---|---|

| Minimum Order: | 1 piece |

| Payment Terms: | T/T, Western Union, MoneyGram |

| Port of Export: | Shanghai |

Product Details

| Model No.: | Brand Name: | Moresuperhard |

|---|

| Certification: | ISO9001 |

|---|---|

| Specification: |

brief introduction:

Polycrystalline diamond (PCD) core integrally bonded to a tungsten-carbide-supported ring which in turn enhances strength of die blanks. |

Packaging & Delivery

| Packaging: | carton box with foam box (Gift package is available) |

|---|---|

| Delivery/Lead Time: | 7-10 work days |

| Production Capacity: | 1000 piece every week |

Product Description

Descriptions of Tungsten Carbide Supported Diamond Die Blanks:

Tungsten carbide supported diamond die blanks is manufactured by means of cold pressing insertion. Polycrystalline diamond (PCD) core integrally bonded to a tungsten-carbide-supported ring which in turn enhances strength of die blanks. All blanks contain metal catalyst in PCD structure. These features give the products stronger ability to withstand wire drawing with high intensity.

Features of Tungsten Carbide Supported Diamond Die Blanks:

1.Special design of taper shape makes the tungsten carbide supported diamond die blanks easy to distinguish between the inlet and the outlet.

2.The alloy ring can protect the material to enable it to bear larger impact.

3.The large external diameter of the alloy ring can provide enough centripetal bearing force for diamond&enough resisting force against wire drawing.

The basic types

1. The steel mold is sufficient for soft metal (such as gold and silver). The steel mold can have multiple holes of different sizes.

2, hard alloy die - drawn wire (steel wire) generally USES hard alloy moulds (Tungsten carbide nib), the typical structure of the mould for a cylindrical (or with a slight taper) of cemented carbide mold core closely embedded in a circular steel bushing (case), the mold core in the inner hole Bell mouth radius, (Bell), the inlet cone (Entrance angel), deformation (work) cone (approach Angle) and sizing of all (bearing) and outlet Angle (back relief).

3. Steel wire molds -- non-ferrous metal wires, such as copper and aluminum, are mostly used with drawing molds similar to steel wire molds. There are some differences in the shape of internal holes.

Polycrystal molds - fine thread can be used to polycrystal molds (artificial diamonds), as well as drawing molds using natural diamonds.

Specifications of Tungsten Carbide Supported Diamond Die Blanks:

ADDMA code Product code Total blank diameter (mm) Diamond diameter (mm) Diamond thickness (mm) Maximum recommended hole size (mm) Grain sizes available (um)

D12 T4015 8.12 4.0 1.5 1.0 5,10,15,25,50

D15 T4023 8.12 4.0 2.3 1.8 5,10,15,25,50

D18 T4029 8.12 4.0 2.9 2.3 5,10,15,25,50

D21 T7040 13.65 7.0 4.0 3.5 5,10,15,25,50

D24 T7053 13.65 7.0 5.3 4.6 5,10,15,25,50

D27 T13086 24.13 13.0 8.6 6.1 10,15,25,50

D30 T130116 24.13 13.0 11.6 7.6 10,15,25,50

D31 T150120 24.13 15.0 12.0 8.0 25,50

D33 T150150 26.80 15.0 15.0 11.0 25,50

ADDMA NO. Dimensions Concentricity(mm) Maximum hole size Available grain size

(μ) Shape

d D t

Self-supported die blanks

D6 2.5 – 1.0 – 0.5 3,5,10,25 Round,

Hexgan

D12 3.2 – 1.5 – 1.0 3,5,10,25

D15 5.2 – 2.5 – 1.5 3,5,10,25

D18 5.2 – 3.5 – 2.0 3,5,10,25

Tungsten carbide supported die blanks

D12 1.5 4.00 1.5 0.20 0.8 3,5,10,25,50

D15 4.0 8.12 2.3 0.25 1.8 3,5,10,25,50

D18 4.0 8.12 2.9 0.25 2.3 3,5,10,25,50

D21 7.0 13.65 4.0 0.35 3.5 3,5,10,25,50

D24 7.0 13.65 5.3 0.40 4.6 3,5,10,25,50

D27 9.0 14.50 7.5 0.40 5.4 10,25,50

D27 13.0 24.13 9.0 0.33 5.8 10,25,50

D30 13.0 24.13 12.0 0.33 7.6 10,25,50

D33 16.0 24.13 16.0 0.33 10.5 25,50

D36 19.0 35.00 19.0 0.60 12.7 25,50

Effect of different materials on life of drawing die

1. Cemented carbide

Carbide for drawing die is carbide - cobalt alloy with low co content. It has good abrasion resistance, impact resistance, polishing and corrosion resistance. It is easy to repair and cheap.The research shows that by improving the composition and structure of cemented carbide, controlling the fluctuation value of carbon content and refining the carbide particles, the properties of the material can be improved and the service life can be extended.At home and abroad, hot isostatic pressure (HIP) treatment, ultra-fine grain technology and addition of rare earth elements are adopted to reduce porosity, refine grain, improve alloy hardness and reduce friction coefficient.The diamond film or titanium nitride coating is formed on the surface of cemented carbide by chemical vapor deposition (CVD) and physical gas deposition (PVD) to improve the surface strength of the alloy.

2. Natural diamond

Natural diamond, commonly known as diamond, is the hardest material in nature, with high abrasion resistance and heat conductivity. It can improve the surface quality of the silk material, improve the properties and size accuracy of the silk material when used for stretching tungsten and molybdenum filaments.However, it is very brittle, poor impact resistance, and hardness of anisotropic, easy to do drawing die wear.In addition, diamond is scarce, expensive and difficult to process, so it is limited in stretching and thick silk.

3. Artificial diamond

Synthetic diamond, also known as polycrystalline diamond, is a polycrystal formed by the non-directional polymerization of many single crystal particles. It has high strength and hardness, strong impact resistance, uniform properties and good comprehensive performance.In drawing and filament, the service life is higher than that of diamond die and cemented carbide die.However, the grains of artificial polycrystalline diamond are larger and difficult to polish. The surface finish of stretched filament is not as good as that of natural diamond.By refining the grain, the polishing performance can be improved, and the natural diamond can be replaced on the drawing die of medium and fine wires, which greatly reduces the cost and improves the product quality.

Note:

1. Die blanks must be cased below 650℃

2. ADDMA: American Diamond Die Manufacturers Association.

3. D: Total Blank Diameter d: Diamond Diameter T: Diamond Thickness

4. Maximum recommended die size for soft nonferrous wire. Hard wire diameter normally should not exceed 65% of this diameter.

Why choose our product

More SuperHard Products Co., Ltd is dedicated to finding solutions that help our clients in all markets succeed. More SuperHard has been manufacturing high-quality, competitively priced superabrasive diamond and cbn tools that are designed to perform in a wide range of industrial ,such as pcd tools grinding, natural diamond polishing, auto parts processing , thermal spray coated industry, optical glass, semicon and led industry, woodworking tool , cnc tool grinding and roll machining ,others ultral precision industry.

The company production and sales of products covered vitrified bond tools, resin bond tools, metal bond tools, electroplated diamond/cbn tools, vaccum brazed products, cvd diamond tools, polycrystalline diamond (pcd) tools, cubic boron nitride (cbn) tools.our objective is to meet all the customers’ needs and help every customer achieve maximum benefits. more brings in revenue for you, you win, we win!

More SuperHard supplies the wheels for several application mainly:

1.Carbide round tools on cnc machines : flute grinding, gash grinding, end facing, clearance angle and cylindrical grinding .

2. Insert grinding for machines such as: agathon, wendt, haas, waida and ewag.

3.Woodworking saw blade and tools .

4.Hss tools

5.Cutting wheels

Products Range:

1. vitrified bond/resin bond/Metal bond/Electroplated diamond grinding wheel & other diamond tools

2. PCD milling tools, PCD turning tools, PCD drilling tools, PCD engraving tools, PCD/pcbn inserts, PCD/pcbn cutting tools, PCD/pcbn grooving tools, CBN inserts

3. PCD/TSP diamond, CVD diamond tools, large size synthetic diamond, Natural diamond tools, diamond abrasive tools

4. diamond grinding&cutting discs, diamond cutting blade, diamond cup wheel, diamond dressers

5. Roller cutting tools, PDC cutters, PDC drill bits& PDC core bits

6. PCD tool grinder & PCD grinding machine

Our product’s advantages:

1.High grinding efficiency

2.Wonderful edge quality

3.Long service life

4.High polishing efficiency

5.Large Exports

6.Considerable after-sell service

7.Amazing performance

8.Various types and sizes available

9.Direct Factory Manufacturer

10.Backing/substrate material: Aluminum

11.Abrasive layer: diamond

12.Bond: vitrified

13.Excellent cutting edges

14.Reduced cycle times

15.Custom Engineered

If you have any questions, please contact us

Whats App:+8618638297665

Skype:18638297665

*

Tel:18638297665

URL:*

To meet your requirements in every way, we need the following information

----- Shape and Dimension of the wheels

----- Grit size (Mesh, refer to Table#1)

----- Concentration

----- Bond(Resinoid, Vitrified, Metallic, Electroplated)

----- Quantity

Descriptions of Tungsten Carbide Supported Diamond Die Blanks:

Tungsten carbide supported diamond die blanks is manufactured by means of cold pressing insertion. Polycrystalline diamond (PCD) core integrally bonded to a tungsten-carbide-supported ring which in turn enhances strength of die blanks. All blanks contain metal catalyst in PCD structure. These features give the products stronger ability to withstand wire drawing with high intensity.

Features of Tungsten Carbide Supported Diamond Die Blanks:

1.Special design of taper shape makes the tungsten carbide supported diamond die blanks easy to distinguish between the inlet and the outlet.

2.The alloy ring can protect the material to enable it to bear larger impact.

3.The large external diameter of the alloy ring can provide enough centripetal bearing force for diamond&enough resisting force against wire drawing.

The basic types

1. The steel mold is sufficient for soft metal (such as gold and silver). The steel mold can have multiple holes of different sizes.

2, hard alloy die - drawn wire (steel wire) generally USES hard alloy moulds (Tungsten carbide nib), the typical structure of the mould for a cylindrical (or with a slight taper) of cemented carbide mold core closely embedded in a circular steel bushing (case), the mold core in the inner hole Bell mouth radius, (Bell), the inlet cone (Entrance angel), deformation (work) cone (approach Angle) and sizing of all (bearing) and outlet Angle (back relief).

3. Steel wire molds -- non-ferrous metal wires, such as copper and aluminum, are mostly used with drawing molds similar to steel wire molds. There are some differences in the shape of internal holes.

Polycrystal molds - fine thread can be used to polycrystal molds (artificial diamonds), as well as drawing molds using natural diamonds.

Specifications of Tungsten Carbide Supported Diamond Die Blanks:

ADDMA code Product code Total blank diameter (mm) Diamond diameter (mm) Diamond thickness (mm) Maximum recommended hole size (mm) Grain sizes available (um)

D12 T4015 8.12 4.0 1.5 1.0 5,10,15,25,50

D15 T4023 8.12 4.0 2.3 1.8 5,10,15,25,50

D18 T4029 8.12 4.0 2.9 2.3 5,10,15,25,50

D21 T7040 13.65 7.0 4.0 3.5 5,10,15,25,50

D24 T7053 13.65 7.0 5.3 4.6 5,10,15,25,50

D27 T13086 24.13 13.0 8.6 6.1 10,15,25,50

D30 T130116 24.13 13.0 11.6 7.6 10,15,25,50

D31 T150120 24.13 15.0 12.0 8.0 25,50

D33 T150150 26.80 15.0 15.0 11.0 25,50

ADDMA NO. Dimensions Concentricity(mm) Maximum hole size Available grain size

(μ) Shape

d D t

Self-supported die blanks

D6 2.5 – 1.0 – 0.5 3,5,10,25 Round,

Hexgan

D12 3.2 – 1.5 – 1.0 3,5,10,25

D15 5.2 – 2.5 – 1.5 3,5,10,25

D18 5.2 – 3.5 – 2.0 3,5,10,25

Tungsten carbide supported die blanks

D12 1.5 4.00 1.5 0.20 0.8 3,5,10,25,50

D15 4.0 8.12 2.3 0.25 1.8 3,5,10,25,50

D18 4.0 8.12 2.9 0.25 2.3 3,5,10,25,50

D21 7.0 13.65 4.0 0.35 3.5 3,5,10,25,50

D24 7.0 13.65 5.3 0.40 4.6 3,5,10,25,50

D27 9.0 14.50 7.5 0.40 5.4 10,25,50

D27 13.0 24.13 9.0 0.33 5.8 10,25,50

D30 13.0 24.13 12.0 0.33 7.6 10,25,50

D33 16.0 24.13 16.0 0.33 10.5 25,50

D36 19.0 35.00 19.0 0.60 12.7 25,50

Effect of different materials on life of drawing die

1. Cemented carbide

Carbide for drawing die is carbide - cobalt alloy with low co content. It has good abrasion resistance, impact resistance, polishing and corrosion resistance. It is easy to repair and cheap.The research shows that by improving the composition and structure of cemented carbide, controlling the fluctuation value of carbon content and refining the carbide particles, the properties of the material can be improved and the service life can be extended.At home and abroad, hot isostatic pressure (HIP) treatment, ultra-fine grain technology and addition of rare earth elements are adopted to reduce porosity, refine grain, improve alloy hardness and reduce friction coefficient.The diamond film or titanium nitride coating is formed on the surface of cemented carbide by chemical vapor deposition (CVD) and physical gas deposition (PVD) to improve the surface strength of the alloy.

2. Natural diamond

Natural diamond, commonly known as diamond, is the hardest material in nature, with high abrasion resistance and heat conductivity. It can improve the surface quality of the silk material, improve the properties and size accuracy of the silk material when used for stretching tungsten and molybdenum filaments.However, it is very brittle, poor impact resistance, and hardness of anisotropic, easy to do drawing die wear.In addition, diamond is scarce, expensive and difficult to process, so it is limited in stretching and thick silk.

3. Artificial diamond

Synthetic diamond, also known as polycrystalline diamond, is a polycrystal formed by the non-directional polymerization of many single crystal particles. It has high strength and hardness, strong impact resistance, uniform properties and good comprehensive performance.In drawing and filament, the service life is higher than that of diamond die and cemented carbide die.However, the grains of artificial polycrystalline diamond are larger and difficult to polish. The surface finish of stretched filament is not as good as that of natural diamond.By refining the grain, the polishing performance can be improved, and the natural diamond can be replaced on the drawing die of medium and fine wires, which greatly reduces the cost and improves the product quality.

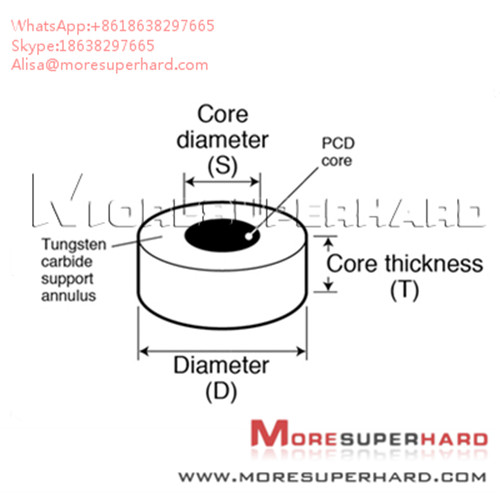

Note:

1. Die blanks must be cased below 650℃

2. ADDMA: American Diamond Die Manufacturers Association.

3. D: Total Blank Diameter d: Diamond Diameter T: Diamond Thickness

4. Maximum recommended die size for soft nonferrous wire. Hard wire diameter normally should not exceed 65% of this diameter.

Why choose our product

More SuperHard Products Co., Ltd is dedicated to finding solutions that help our clients in all markets succeed. More SuperHard has been manufacturing high-quality, competitively priced superabrasive diamond and cbn tools that are designed to perform in a wide range of industrial ,such as pcd tools grinding, natural diamond polishing, auto parts processing , thermal spray coated industry, optical glass, semicon and led industry, woodworking tool , cnc tool grinding and roll machining ,others ultral precision industry.

The company production and sales of products covered vitrified bond tools, resin bond tools, metal bond tools, electroplated diamond/cbn tools, vaccum brazed products, cvd diamond tools, polycrystalline diamond (pcd) tools, cubic boron nitride (cbn) tools.our objective is to meet all the customers’ needs and help every customer achieve maximum benefits. more brings in revenue for you, you win, we win!

More SuperHard supplies the wheels for several application mainly:

1.Carbide round tools on cnc machines : flute grinding, gash grinding, end facing, clearance angle and cylindrical grinding .

2. Insert grinding for machines such as: agathon, wendt, haas, waida and ewag.

3.Woodworking saw blade and tools .

4.Hss tools

5.Cutting wheels

Products Range:

1. vitrified bond/resin bond/Metal bond/Electroplated diamond grinding wheel & other diamond tools

2. PCD milling tools, PCD turning tools, PCD drilling tools, PCD engraving tools, PCD/pcbn inserts, PCD/pcbn cutting tools, PCD/pcbn grooving tools, CBN inserts

3. PCD/TSP diamond, CVD diamond tools, large size synthetic diamond, Natural diamond tools, diamond abrasive tools

4. diamond grinding&cutting discs, diamond cutting blade, diamond cup wheel, diamond dressers

5. Roller cutting tools, PDC cutters, PDC drill bits& PDC core bits

6. PCD tool grinder & PCD grinding machine

Our product’s advantages:

1.High grinding efficiency

2.Wonderful edge quality

3.Long service life

4.High polishing efficiency

5.Large Exports

6.Considerable after-sell service

7.Amazing performance

8.Various types and sizes available

9.Direct Factory Manufacturer

10.Backing/substrate material: Aluminum

11.Abrasive layer: diamond

12.Bond: vitrified

13.Excellent cutting edges

14.Reduced cycle times

15.Custom Engineered

If you have any questions, please contact us

Whats App:+8618638297665

Skype:18638297665

*

Tel:18638297665

URL:*

|

SUPPLIER PROFILE

|

|||

|---|---|---|---|

| Company: | Henan More Super Hard Products Co.,Ltd | ||

| City/State | Zhengzhou, Henan | Country: |

China

|

| Business Type: | Export - Manufacturer / Trading Company | Established: | 2014 |

| Member Since: | 2018 | Contact Person | 'Alisa Zhang' |

SUPPLIER PROFILE

City/State/Country -

Zhengzhou, Henan

China

Business Type -

Export - Manufacturer / Trading Company

Established -

2014

Member Since -

2018

Contact Person -

'Alisa Zhang'