Advertisements

Surface coating hot spraying resin bond diamond grinding wheel [email protected]

| Price: | US$ 50 / Piece |

|---|---|

| Minimum Order: | 1 piece |

| Payment Terms: | T/T, Western Union, MoneyGram |

| Port of Export: | Shanghai |

Product Details

| Model No.: | 1A1 | Brand Name: | Moresuperhard |

|---|

| Certification: | ISO9001 |

|---|---|

| Specification: | More SuperHard company provides a full range of thermal spray coating solution and service which includes OD grinding, inside grinding, cylindrical grinding, surface grinding and polishing, etc.We have been present on the Thermal Spraying Coating industry for over 10 years . Our resin diamond wheels for HVOF carbide coating has enjoyed wide popularity in Canada, Turkey, Dubai, etc. Our products cover cylindrical resin diamond wheels , diamond internal grinding wheels and flexible diamond sand belts. |

Packaging & Delivery

| Packaging: | carton box with foam box (Gift package is available) |

|---|---|

| Delivery/Lead Time: | 7-10 work days |

| Production Capacity: | 1000 piece every week |

Product Description

What Is The Thermal Spray Coating

Thermal spraying is an industrial coating process that consists of a heat source (flame or other) and a coating material in a powder or wire form which is literally melted into tiny droplets and sprayed onto surfaces at high velocity. Thermal sprayed coatings uniquely enhance and improve the performance of the component.

Advantages Of Thermal Spraying Coating

Good wear resistance, high temperature to enhance the performances of parts

Can change the parts surfaces' properties like electric conductive or isolative, or to build the undersized parts.

The thermal spray substrate remains comparatively low temperature (200®C or lower, approx.) during spraying, which allows the subject to maintain its organizational structure and physical properties.

Modification is possible even for large and complex-shaped equipment, down to small parts.

Thermal spraying can provide thick coatings (thickness range from 20 microns to several mm), over a large area at high deposition rate as compared to other coating processes such as electroplating, physical and chemical vapor deposition.

Applications Of Thermal Spraying Coating

* Automotive. Reducing fuel consumption and emissions using specialized coatings for engine, transmission, steering, and suspension components.

* Aviation. aero engine, airframe and landing gear

* Chemical Processing. biochemicals, biofuels, bioplastics, chemicals and plastics

* Medical. medical implants like hip joints and dental implants.

* Oil and Gas. Exploration drilling, liquefied natural gas, oil sand, pipeline, shale coal seam Gas and subsea

* Power Generation. high-temperature, erosion-corrosion protection in boilers on waterwalls and superheaters, steam turbine,critical turbine components, pump and valve bodies, impellers and rotors.steel components of wind turbines

* Pulp and Paper.corrosion coatings on pulp digesters, and wear-control coverings with controlled surface textures for paper machinery such as calendar and embossing rolls

* Water. coatings for tanks and pipelines,erosion-, abrasion- and impact-resistant coatings for pumps and valves

Thermal Spray Coating Process

Thermal Spray technologies includ Flame wire spray, Arc spray, Plasma spray, HVOF or HVAF , Detonation Spray, Cold spray .Thermal spraying technology is widely used in aerospace, aviation, machinery, metallurgy, chemical, petroleum, coal, railway, textile and many other departments .

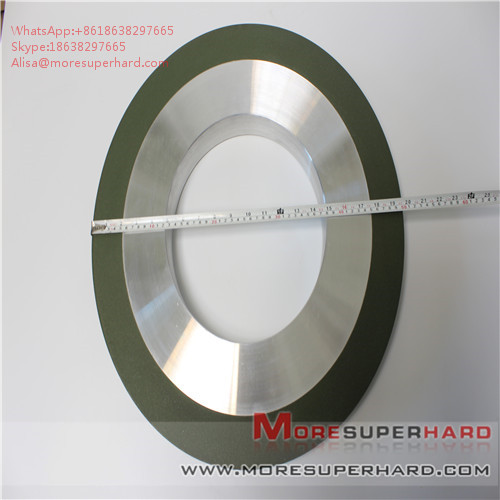

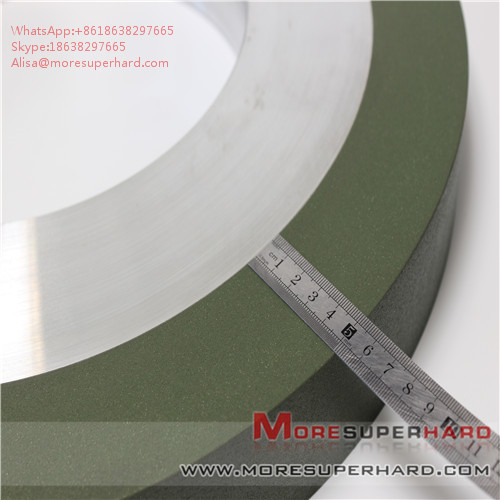

Specifications Of Resin Bond Diamond Grinding Wheel For Thermal Spraying

Diameter (mm) Diameter (inch) H (mm) T (mm) X (mm)

25 1 inch 6 12 6

30 - 12 6 -

40 - 12 6 -

50 2 inch 6 12 6

100 4 inch 12 12 10

150 6 inch 12 25 10

300 12 inch - 25 10

400 16 inch 127 25, 50 10, 25

500 20 inch 127, 203.2 25, 50 10, 25

600 24 inch 254 25, 50 10, 16, 25

750 30 inch 304.8 50 10

914.4 36 inch 304.8 25, 50 10, 25

1100 43 inch 304.8 50 10

Other specification can be made according to customer requirement

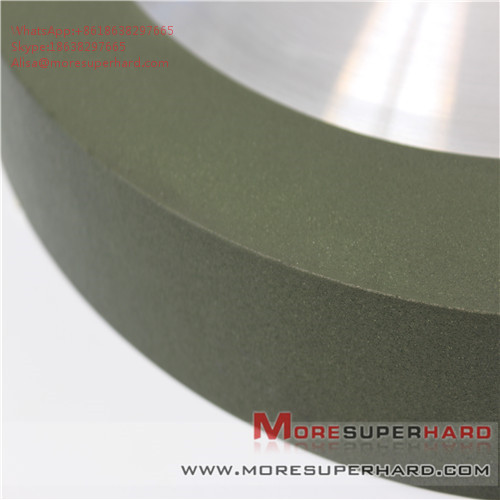

Resin Bond diamond grinding Wheels are designed for fast and cool cutting,perform well in both wet and dry grinding applications. For grinding and finishing of ceramics,precision grinding on carbide dies, rolls and carbide wear parts and other hard-to-grind materials.

The Production Process of 1A1 resin bond diamond grinding wheel:

1.machine work: 1A1 resin bond diamond grinding wheel in the workshop

2.Dynamic balance test:1A1 resin bond diamond grinding wheel

3.The precise measurement:resin bond diamond grinding wheel

4.The meticulous cleaning:resin bond diamond grinding wheel

5.The packing process: resin bond diamond grinding wheel

Thermal Spray Technologies Include

Flame spray (wire,rod,powder), Arc spray, Plasma spray (includes atmosphere controlled plasma spray), HVOF (high velocity oxygen and fuel spray) or HVAF(high velocity air and fuel spray), Detonation Spray, Cold spray

Thermal spraying methods Application cases of thermal spray coating

HVOF (high velocity oxygen and fuel spray) Spraying of cermet such as chromium carbide type materials

* High-temperature oxidation resistance turbine blade

* Anti-slip bridle roll

* Abrasion resistance paper manufacturing roll, etc

Arc spraying Attainment of thick overlay spraying as thick as 20mm.

Such as piston

Flame spraying (wire, rod, powder) Rust preventive spraying for aluminum and zinc, etc

* Backup roll chuck

* Induction heating pot

* Abrasion resistance plunger

* Abrasion resistance sleeve

Water plasma spraying Perfect for large-format, thick covering applications. oxide type ceramics materials

* Carbon plating

* Abrasion resistance,corrosion resistance conveyor pulley, Paper manufacturing roll

* Ceramic molds

Why choose our product

More SuperHard Products Co., Ltd is dedicated to finding solutions that help our clients in all markets succeed. More SuperHard has been manufacturing high-quality, competitively priced superabrasive diamond and cbn tools that are designed to perform in a wide range of industrial ,such as pcd tools grinding, natural diamond polishing, auto parts processing , thermal spray coated industry, optical glass, semicon and led industry, woodworking tool , cnc tool grinding and roll machining ,others ultral precision industry.

The company production and sales of products covered vitrified bond tools, resin bond tools, metal bond tools, electroplated diamond/cbn tools, vaccum brazed products, cvd diamond tools, polycrystalline diamond (pcd) tools, cubic boron nitride (cbn) tools.our objective is to meet all the customers’ needs and help every customer achieve maximum benefits. more brings in revenue for you, you win, we win!

More SuperHard supplies the wheels for several application mainly:

1.Carbide round tools on cnc machines : flute grinding, gash grinding, end facing, clearance angle and cylindrical grinding .

2.Insert grinding for machines such as: agathon, wendt, haas, waida and ewag.

3.Woodworking saw blade and tools .

4.Hss tools

5.Cutting wheels

Products Range:

1. vitrified bond/resin bond/Metal bond/Electroplated diamond grinding wheel & other diamond tools

2. PCD milling tools, PCD turning tools, PCD drilling tools, PCD engraving tools, PCD/pcbn inserts, PCD/pcbn cutting tools, PCD/pcbn grooving tools, CBN inserts

3. PCD/TSP diamond, CVD diamond tools, large size synthetic diamond, Natural diamond tools, diamond abrasive tools

4. diamond grinding&cutting discs, diamond cutting blade, diamond cup wheel, diamond dressers

5. Roller cutting tools, PDC cutters, PDC drill bits& PDC core bits

6. PCD tool grinder & PCD grinding machine

Our product’s advantages:

1.High grinding efficiency

2.Wonderful edge quality

3.Long service life

4.High polishing efficiency

5.Large Exports

6.Considerable after-sell service

7.Amazing performance

8.Various types and sizes available

9.Direct Factory Manufacturer

10.Backing/substrate material: Aluminum

11.Abrasive layer: diamond

12.Bond: vitrified

13.Excellent cutting edges

14.Reduced cycle times

15.Custom Engineered

Packaging and shipping

Packing Carton, plastic bag,or as your request

Shipping we use DHL,UPS,FEDEX,ect.to ship the goods,or according to the customer's requirement

Delivery time about3-7days, for special time according to your quantity

Our services

1. Quick Response: Your inquiry will be replied within 24 hours.

2. Competitive Price : Directly from factory to save your money.

3. after-sales warranty : Once there is problem after you received products, you can contact us in time. We will resolve it in short time.

4. Flexibility: Small orders are acceptable for quick delivery and to help you reduce stock cost.

5. OEM service: Custom fabrication according to your drawings ,samples or designs.

FAQ:

Q1. Can negotiate the price?

A: yes, you can. We will give some discount according to your quantity.

Q2. How can now my order’s production progress?

A: we will keep closely track the production and shipment progress. And we will inform you with the newest progress about producing and shipping.

Q3. How can you ensure your quality?

A: We have pass the ISO 9001:2008. If there is any problem with our products, please send me the detailed picture of the problem, once we verify it, we will change the products for you within 30 days.

Q4: When I contact you is suitable?

You can contact Us at any time, we promise that we will reply you within 12 hours.

A:So, please contact me for more information about our product, service and related issues.

If you have any questions, please contact us

Whats App:+8618638297665

Skype:18638297665

*

Tel:18638297665

URL:*

To meet your requirements in every way, we need the following information

----- Shape and Dimension of the wheels

----- Grit size (Mesh, refer to Table#1)

----- Concentration

----- Bond(Resinoid, Vitrified, Metallic, Electroplated)

----- Quantity

|

SUPPLIER PROFILE

|

|||

|---|---|---|---|

| Company: | Henan More Super Hard Products Co.,Ltd | ||

| City/State | Zhengzhou, Henan | Country: |

China

|

| Business Type: | Export - Manufacturer / Trading Company | Established: | 2014 |

| Member Since: | 2018 | Contact Person | 'Alisa Zhang' |

SUPPLIER PROFILE

City/State/Country -

Zhengzhou, Henan

China

Business Type -

Export - Manufacturer / Trading Company

Established -

2014

Member Since -

2018

Contact Person -

'Alisa Zhang'