Advertisements

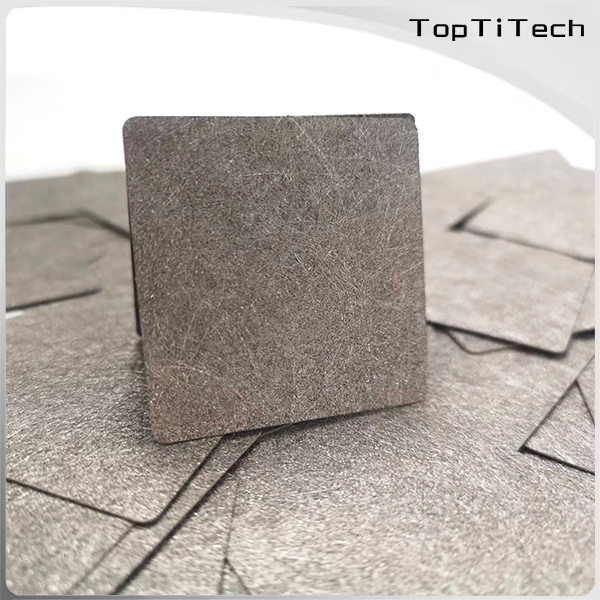

Sintered Nickel Fiber Felt For AEM Electrolyzer

| Price: | US$ 10 / Square Meter |

|---|---|

| Minimum Order: | 1 m2 |

| Payment Terms: | LC、T/T、D/P、D/A、O/A |

| Port of Export: | FOB/EXW/CIF SHANGHAI OR TIANJIN |

Product Details

| Model No.: | nickel | Brand Name: | TOPTITECH |

|---|

| Certification: | ISO9001:2015 |

|---|---|

| Specification: |

Material: N4 N6 N8 Ni200 Ni201

Thickness: 0.25mm, 0.4mm, 0.5mm, 0.6mm, 0.8mm ,1.0mm, etc. Micron: 3-100um Size: 50x50mm, 100x100mm, 200x200mm, 500x500mm, 1000x1000mm, other size can be customized. Porosity: 50%-90% |

Packaging & Delivery

| Packaging: | Wooden box or carton box |

|---|---|

| Delivery/Lead Time: | in 10 days |

| Production Capacity: | 100000 PCS/WEEK |

Product Description

https://*/microporous-filter-components/sintered-nickel-fiber-felt-for-pem.html

Nickel fiber felt is a high-performance material made from pure micron-level nickel fibers using a special felt laying process and ultra-high temperature vacuum sintering process.

This material offers several advantages over nickel mesh or nickel powder sintered plates due to its excellent three-dimensional network porous structure, high porosity, large specific surface area, uniform pore size distribution, strong corrosion resistance, good water permeability, good heat dissipation, stable performance. Additionally, nickel fiber felt has a long life expectancy.

Detailed Specifications

Material: N4 N6 N8 Ni200 Ni201

Thickness: 0.25mm, 0.4mm, 0.5mm, 0.6mm, 0.8mm ,1.0mm, etc.

Micron: 3-100um

Size: 50x50mm, 100x100mm, 200x200mm, 500x500mm, 1000x1000mm, other size can be customized.

Porosity: 50%-90%

Features:

1.Good conductivity

2.High mechanical strength

3.Good chemical stability

4.Strong corrosion resistance

Manufacturing flow

Nickel wire→Cluster drawing→Nickel fiber→Fiber shear→Air-laid→Sintering→Nickel fiber felt

Nickel fiber felt is manufactured through a process that involves cluster drawing of nickel wire, fiber shearing, air-laid netting, and sintering. The key step in this process is fiber drawing, which is performed using the cluster drawing method. Compared to other methods, cluster drawing offers advantages such as uniform wire diameter, easy continuous production, and low cost. This method can produce nickel fibers with different wire diameters ranging from 6 μm to 40 μm to meet the requirements of different types of nickel fiber mats.

The fiber shearing process is carried out using a special cutting machine that produces fibers of uniform length and high production efficiency. These fibers are then laid into a net using the air flow method with an imported felt laying unit. By adjusting various process parameters, the resulting nickel fiber net has good uniformity with no defects such as bundled fibers or fiber agglomeration. The single weight can also be controlled as needed.

Application field

1.AEM electrolyzer diffusion layer;

2.Hydrogen fuel;

3.Hydrogen suction machine;

4.Fuel cells;

5.Gas Diffusion Layer (GDL);

6.Battery electrode material;

7.Heat exchange and adsorption materials

|

SUPPLIER PROFILE

|

|||

|---|---|---|---|

| Company: | Toptitech | ||

| City/State | Baoji, 陕西 | Country: |

China

|

| Business Type: | Export - Manufacturer / Trading Company | Established: | 2011 |

| Member Since: | 2023 | Contact Person | Lisa Yue |

SUPPLIER PROFILE

City/State/Country -

Baoji, 陕西

China

Business Type -

Export - Manufacturer / Trading Company

Established -

2011

Member Since -

2023

Contact Person -

Lisa Yue