Advertisements

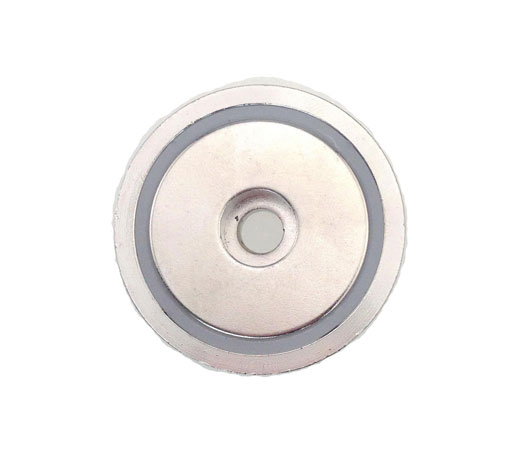

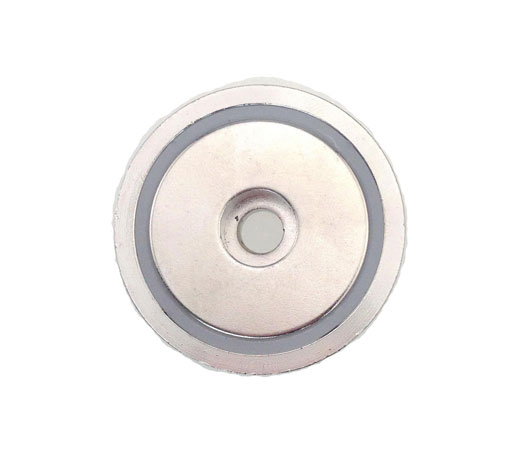

Pot Magnets With Bore

| Price: | US$ 1000 |

|---|---|

| Minimum Order: | 1pc |

| Payment Terms: | T/T |

| Port of Export: |

Product Details

| Model No.: | Brand Name: |

|---|

| Certification: | |

|---|---|

| Specification: | Leyuan Group Co., Ltd. is an experienced magnetic products manufacturer. We focus on the production of magnetic product related to permanent magnets. |

Packaging & Delivery

| Packaging: | anti-magnetism packing |

|---|---|

| Delivery/Lead Time: | 2-15 days |

| Production Capacity: | 10000pcs per month |

Product Description

Leyuan Group Co., Ltd. is an experienced magnetic products manufacturer. We focus on the production of magnetic product related to permanent magnets.

These neodymium magnets with countersunk holes/neodymium disc countersunk hole magnets have only one surface that has strong magnetism; the other surface of the strong magnets with hole just has very weak magnetism.

Leyuan round countersunk magnets have excellent holding forces thanks to the use of anisotropic neodymium (NdFeB) magnets. The maximum working temperature of these types is up to 80®C, and the steel body is galvanized. These types are used in applications where high holding forces and small dimensions are required.

Application: magnet source round base magnet can be inserted into different instruments, machines, and tools. These countersunk rare earth magnets can be used effectively as auxiliary instruments during transport, clamping, mounting, lifting, welding, separation, etc. The best holding force is reached at full contact of the magnetic face with the ground ferromagnetic surface. Force is vertical to the base (air gap = 0 mm). Small cracks on the neodymium round base magnet or steel pot do not have any influence as to the functionality, lifetime, and holding force of the pot magnet.

The Specification of Countersunk Pot Magnets With Bore

Counterbore Stamp

Pot magnet (NdFeB), with counter bore, Nickel coating, body stamping machining.

Model D D1 D2 H Weight (g) Pull force (Kgf)

103-16 16 3.5 6.5 5.2 7 6

103-20 20 4.5 8.6 7.2 15 9

103-25 25 5.5 10.6 7.7 24 19

103-32 32 5.5 10.6 7.8 39 32

103-36 36 6.5 12 7.6 50 41

103-40 40 6.5 12 7.8 69 52

103-42 42 6.5 12 8.8 77 61

103-48 48 8.5 19 10.8 120 75

103-60 60 8.5 19 15 243 115

103-75 75 10.5 21 17.8 480 163

103-16L 16 3.5 6.5 5.2 7 5

103-20L 20 4.5 8.6 6 13 8

103-25L 25 5.5 10.6 6.9 23 17

103-32L 32 5.5 10.6 6.8 38 30

103-36L 36 6.5 12 6.9 50 39

103-42L 42 6.5 12 7.9 78 58

103-48L 48 8.5 19 9.6 113 72

103-60L 60 8.5 19 15 265 115

103-75L 75 10.5 21 17.8 537 163

103-16P 16 3.5 6.5 5.2 7 8

103-20P 20 4.5 8.6 7.2 15 11

103-25P 25 5.5 10.6 7.7 24 24

103-32P 32 5.5 10.6 7.8 39 40

103-36P 36 6.5 12 7.6 50 51

103-40P 40 6.5 12 7.8 69 65

103-42P 42 6.5 12 8.8 77 76

103-48P 48 8.5 19 10.8 120 94

103-60P 60 8.5 19 15 243 144

103-75P 75 10.5 21 17.8 480 204

Counterbore Lathe

Pot magnet (NdFeB), with counter bore, Nickel coating, body lathe machining.

Model D D1 D2 H Weight (g) Pull force (Kgf)

104-10 10 3.5 6.5 5 3 1

104-12 12 3.5 6.5 5 4 1.5

104-14 14 3.5 6.5 4.5 5 4

104-16 16 3.5 6.5 5.2 7 6

104-18 18 4.5 8.6 6 10 8

104-20 20 4.5 8.6 7.2 15 9

104-22 22 4.5 8.6 6.9 18 15

104-25 25 5.5 10.6 7.7 24 19

104-28 28 5.5 10.6 6.4 28 25

104-30 30 5.5 10.6 6.4 32 29

104-32 32 5.5 10.6 7.8 39 32

104-34 34 5.5 10.6 7.3 45 35

104-36 36 6.5 12 7.6 50 41

104-38 38 6.5 12 7.4 60 47

104-40 40 6.5 12 7.8 69 52

104-42 42 6.5 12 8.8 77 61

104-45 45 6.5 12 8.7 90 70

104-48 48 8.5 19 10.8 120 75

104-50 50 8.5 19 10.7 136 89

104-55 55 8.5 19 12 192 102

104-60 60 8.5 19 15 243 115

104-65 65 8.5 19 14.9 338 130

104-70 70 10.5 21 16.9 440 148

104-75 75 10.5 21 17.8 480 163

104-80 80 10.5 21 19 655 250

104-90 90 10.5 21 18 822 340

104-100 100 12.5 25 18 1030 380

104-110 110 12.5 25 18 1226 420

104-120 120 12.5 25 18 1420 480

Straight Hole Stamp

Pot magnet (NdFeB), with bore, Nickel coating, body stamping machining.

Model D D1 D2 H Weight (g) Pull force (Kgf)

105-16 16 3.5 6.5 5.2 7 5

105-20 20 4.5 8 7.2 13 8

105-25 25 5.5 9 7.7 22 17

105-32 32 5.5 9 7.8 38 30

105-36 36 6.5 11 7.6 48 40

105-40 40 6.5 11 7.8 69 50

105-42 42 6.5 11 8.8 75 65

105-48 48 8.5 15 10.8 114 72

105-60 60 8.5 15 15 235 110

105-75 75 10.5 18 17.8 460 155

105-16L 16 3.5 6.5 5.2 7 4

105-20L 20 4.5 8 6 12 7

105-25L 25 5.5 9 6.9 23 16

105-32L 32 5.5 9 6.8 38 28

105-36L 36 6.5 11 6.9 50 38

105-42L 42 6.5 11 7.9 76 62

105-48L 48 8.5 15 9.6 111 69

105-60L 60 8.5 15 15 260 110

105-75L 75 10.5 18 17.8 524 155

105-16P 16 3.5 6.5 5.2 7 6

105-20P 20 4.5 8 7.2 13 10

105-25P 25 5.5 9 7.7 22 21

105-32P 32 5.5 9 7.8 38 38

105-36P 36 6.5 11 7.6 48 50

105-40P 40 6.5 11 7.8 69 63

105-42P 42 6.5 11 8.8 75 81

105-48P 48 8.5 15 10.8 114 90

105-60P 60 8.5 15 15 235 150

105-75P 75 10.5 18 17.8 460 213

Straight Hole Lathe

Pot magnet (NdFeB), with bore, Nickel coating, body lathe machining.

Model D D1 D2 H Weight (g) Pull force (Kgf)

106-10 10 3.5 6.5 5 2 1

106-12 12 3.5 6.5 5 4 1.5

106-14 14 3.5 6.5 4.5 5 3

106-16 16 3.5 6.5 5.2 7 5

106-18 18 4.5 8 6 10 6

106-20 20 4.5 8 7.2 13 8

106-22 22 4.5 8 6.9 17 16

106-25 25 5.5 9 7.7 22 18

106-28 28 5.5 9 6.4 27 23

106-30 30 5.5 9 6.4 32 27

106-32 32 5.5 9 7.8 38 30

106-34 34 5.5 9 7.3 44 33

106-36 36 6.5 11 7.6 48 40

106-38 38 6.5 11 7.4 59 44

106-40 40 6.5 11 7.8 69 50

106-42 42 6.5 11 8.8 75 65

106-45 45 6.5 11 8.7 89 69

106-48 48 8.5 15 10.8 114 72

106-50 50 8.5 15 10.7 134 81

106-55 55 8.5 15 12 189 93

106-60 60 8.5 15 15 235 110

106-65 65 8.5 15 14.9 333 122

106-70 70 10.5 18 16.9 429 138

106-75 75 10.5 18 17.8 460 155

106-80 80 10.5 18 19 641 250

106-90 90 10.5 23 18 799 340

106-100 100 12.5 25 18 1016 380

106-110 110 12.5 25 18 1212 420

106-120 120 12.5 25 18 1380 480

The Advantages of Pot Magnets With Bore

Pot magnets can be inserted into different instruments, machines, tools. Can be used as auxiliary instruments during transport, clamping, mounting, lifting, welding, separation, etc. The best holding force is reached at full contact of the magnetic face with the ground ferromagnetic surface, force is vertical to the base (air gap = 0 mm). Small cracks on the magnet or steel pot do not have any influence to the functionality, lifetime and holding force of the pot magnet.

Other Magnetic Products You May Also Like

START NOW

Email us with any questions or inquiries or use our contact data. We would be happy to answer your questions.

Latest News & Blog

|

SUPPLIER PROFILE

|

|||

|---|---|---|---|

| Company: | Leyuan Group Co., ltd. | ||

| City/State | Ningbo, zhejiang | Country: |

China

|

| Business Type: | Export - Manufacturer / Trading Company | Established: | NA |

| Member Since: | 2021 | Contact Person | Chang Edward |

SUPPLIER PROFILE

City/State/Country -

Ningbo, zhejiang

China

Business Type -

Export - Manufacturer / Trading Company

Established -

NA

Member Since -

2021

Contact Person -

Chang Edward