Advertisements

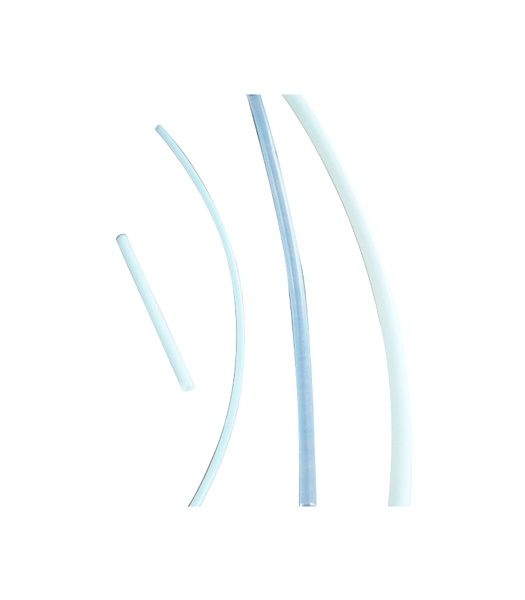

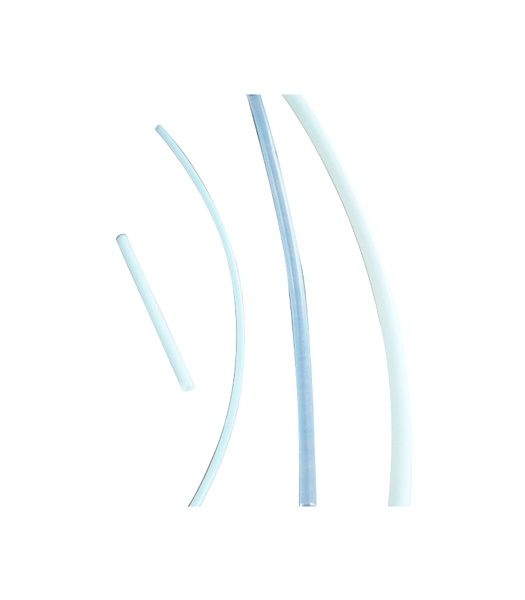

PTFE Extruded Tube

| Price: | € 10 / Acre |

|---|---|

| Minimum Order: | |

| Payment Terms: | TT |

| Port of Export: |

Product Details

| Model No.: | Brand Name: |

|---|

| Certification: | |

|---|---|

| Specification: |

Extruded PTFE tube is frequently employed when a uniform wall thickness is required throughout the entire length of the tube. The polytetrafluoroethylene pipe produced by extrusion process solves the problem of poor shrinkage of PTFE pipe under heat, which can not effectively improve the corrosion resistance, electrical insulation and anti-viscosity of the workpiece. |

Packaging & Delivery

| Packaging: | |

|---|---|

| Delivery/Lead Time: | |

| Production Capacity: |

Product Description

Extruded PTFE tube is frequently employed when a uniform wall thickness is required throughout the entire length of the tube. The polytetrafluoroethylene pipe produced by extrusion process solves the problem of poor shrinkage of PTFE pipe under heat, which can not effectively improve the corrosion resistance, electrical insulation and anti-viscosity of the workpiece. As the leading PTFE tube manufacturer, Xinrui offers high quality extruded PTFE tubing that can be produced in various sizes, lengths, and thicknesses to meet specific application requirements. The PTFE extruded tube can also be further processed, such as adding fillers or reinforcing materials, to enhance its mechanical properties or provide additional functionalities.

Why Choose Xinrui As Your PTFE Extruded Tube Manufacturer?

As a leaing PTFE extruded tube manufacturer in China, Xinrui is committed to providing high-quality PTFE extruded tubes which have excellent dimensional stability, maintaining their shape and size even under varying temperatures and pressures. Our extruded PTFE plastic tubes are renowned for their precise dimensional tolerances. It's important to note that this extrusion process ensures consistent thickness throughout the entire structure of the tubing. We also offer a diverse range of options in our PTFE extruded tubes to cater to a variety of needs. Whether you need standard sizes or custom dimensions, our team is dedicated to providing you with the perfect solution.

PTFE Extruded Tube Specification

Product name Speciations(mm) Remarks

Diameter Length

PTFE pipe Molded tube Outer: 20-600 100-250

Hydraulic tube Outer: 50-300 500-1000 Diameter needs machine processing

Extruded tube Outer: 30-200 <2000 the length can be customized as customer's requirement

Technical Indexes of the PTFE Extruded Tube

Properties The implementation of standards The technical performance index Remarks

The proportion of Tensile strength(Mpa) Crack elongation(%)

Molded rods ZBG33003 SFB-1 2.10-2.30 ≥14 ≥140 QB/T 3626-1999 Light industry standard

Molded pipe Company standard 2.15-2.25 ≥15 ≥150

Hydraulic rod/tube Company standard 2.10-2.20 ≥14 ≥150

Extrusion rods/tube Company standard 2.10-2.20 ≥15 ≥150

PTFE Extruded Tube Uses

Medical Industry Uses: PTFE extruded tubes are used in medical devices and equipment, such as such as catheters, endoscopes, and surgical instruments.

Chemical Industries: Filled PTFE extruded tubes, with fillers like glass fibers or carbon, are used in the chemical industry to enhance the mechanical properties and chemical resistance of PTFE, making them suitable for handling corrosive chemicals.

Electrical Engineering: PTFE extruded tubes are widely used in electrical applications due to their exceptional electrical insulation properties. They serve as insulators, providing insulation and protection against high voltages and harsh environments for wires, cables, and electronic components.

Mechanical Engineering: PTFE extruded tubes find application in mechanical engineering. They are used as bearing pads, bushings, or gaskets to provide low friction, high-temperature resistance, lubricity, wear resistance, and thermal stability in various mechanical systems.

PTFE Extrusion Tube Process

Mixing: through the mixing machine to polytetrafluoroethylene powder and extruder mix.

Storage: storage at 25℃ for 24 hours.

Extrusion molding: extrusion molding through the extruder.

Sintering: the product into the sintering furnace for sintering.

Cooling: after sintering cooling.

The polytetrafluoroethylene pipe produced by extrusion process solves the problem of poor shrinkage of polytetrafluoroethylene pipe under heat, which can not effectively improve the corrosion resistance, electrical insulation and anti-viscosity of the workpiece.

|

SUPPLIER PROFILE

|

|||

|---|---|---|---|

| Company: | Jiangsu Xinrui Plastic Technology Co.,Ltd | ||

| City/State | Yangzhong, Jiangsu | Country: |

China

|

| Business Type: | Export - Manufacturer / Trading Company | Established: | NA |

| Member Since: | 2023 | Contact Person | Bonny Chen |

SUPPLIER PROFILE

City/State/Country -

Yangzhong, Jiangsu

China

Business Type -

Export - Manufacturer / Trading Company

Established -

NA

Member Since -

2023

Contact Person -

Bonny Chen