Advertisements

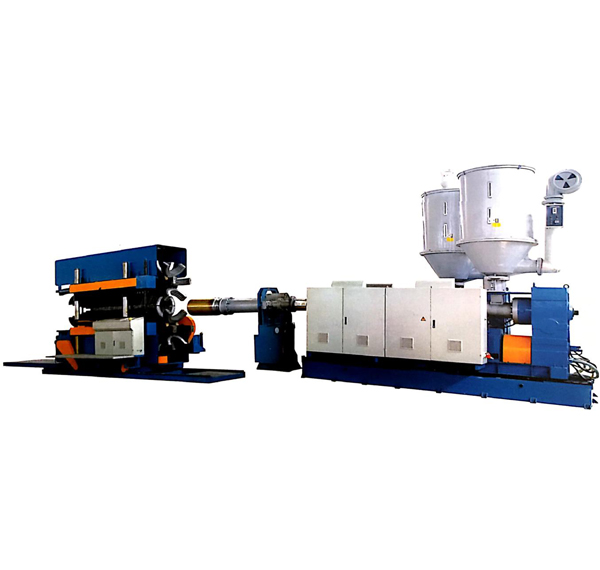

PE/PVC Large Diameter Double Wall Corrugated Pipe Production Line

| Price: | US$ 700000 |

|---|---|

| Minimum Order: | 5 production line/month |

| Payment Terms: | T/T, L/C |

| Port of Export: |

Product Details

| Model No.: | Brand Name: |

|---|

| Certification: | |

|---|---|

| Specification: | High precision and character for forming machine and head die |

Packaging & Delivery

| Packaging: | Stretch film and distillation plate |

|---|---|

| Delivery/Lead Time: | 45 days |

| Production Capacity: | 10 production line/month |

Product Description

1. High precision and character for forming machine and head die

2. Water and wind cooling for module

3. On-line belling

4. Unique digital control system

5. High automatic, high output, stable production condition.

The Parameter of PE/PVC Large Diameter Double Wall Corrugated Pipe Production Line

Model JG-SEG-630 JG-SEG-800

Raw material PVC PE

Extrusion system

Screw dis mm Φ90/180 Φ90/120

L/D ratio L/D 30:1

Driving power KW 90 75/135

Heating zone KW 77 120

Forming system 8 6*2

Number of mould block

Driving power Pair 42 42

Cooling power KW 7.5 7.5

Cooling power KW 11 11

Lubricating power KW 0.75 0.75

Move speed of mould block m/min 0.3-3 0.3-3

Vacuum pump power KW 75 75

Forming length of mould block mm 2286 2286

Spray cooling system

Cooling method Cooled b water and wind

Cooling power KW 9.5 9.5

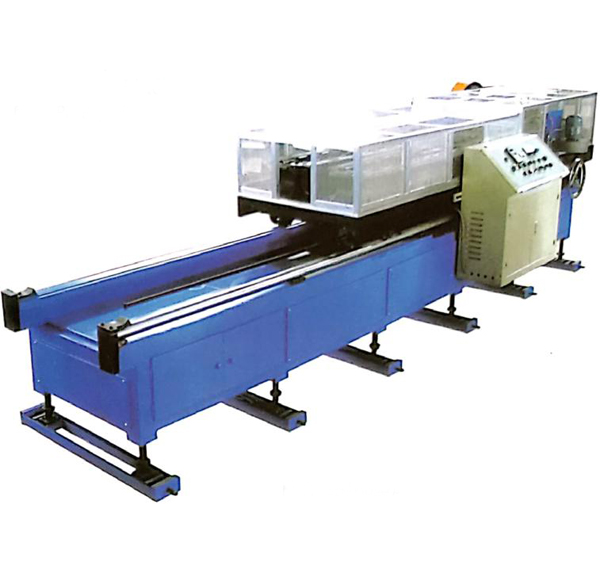

Automatic cutting system

Driving total power KW 10.4 10.4

Cutting method Planetary cutting

Cutting range mm φ200-630 Φ225-800

Others

Range of pipe dia. mm Φ200-630 Φ225-800

Central height mm 1600 1600

Water consumption L/H 6000 6000

Installed capacity(approx) KW 460 650

Normal power KW 300 350

Dimensions(approx) M 39.7*5.2*5.85

Total weight(approx) T 42 45

Production Line

The production process of the Double Wall Corrugated Pipe Production Line

has 5 stages, including:

1. Raw material preparation

The preparation of raw materials starts with the purchase order and ends with the manufacture of the mixture and its transfer to the extruder hopper. This stage includes: purchase order, receiving, storing and manufacturing the mixture.

2. Extrusion

During the extrusion stage of thermoplastics, the polymer is melted by the heat generated inside the extruder. The melting of heavy polyethylene is controlled by precisely adjusting the heat distribution in different areas according to the polymer type, so as to generate the best pressure in the output of the extruder.

3. Corrugation

The extruded polyethylene passes through the die, and the shape of the pipe is obtained at the output end of the die. Then, the outer surface of the double-walled tube is corrugated through a mold and vacuum, while the inner surface of the tube is still smooth. This molding process is carried out continuously through a corrugated rotating mold.

According to the type of pipe required, install the corresponding parts and molds on the production line, stabilize the thickness of the polyethylene pipe layer during the production process, and adjust the production speed and temperature to the best state.

4. Calibration

The cooling phase is very important for the dimensional stability in the production of plastic pipes, which is called calibration, which changes according to the thickness of the pipe and the production speed. To cool the pipe, use water nozzles embedded around the pipe along the calibrator. The water temperature of the cooling system is also controlled.

5. Validation and final product testing

In the final stage of the production process, the bellows are sampled, and the quality control department conducts corresponding tests to determine whether the final product meets the required specifications, and optimizes adjustments.

Qingdao Kailite plastic machinery Co., LTD. is a professional plastic pipe production line manufacturers, we provide double wall corrugated pipe machine, corrugated pipe extrusion line, corrugated tube machine, plastic corrugated pipe production line, corrugated pipe making machine, plastic extrusion line and etc. Want to know more? Please contact us.

|

SUPPLIER PROFILE

|

|||

|---|---|---|---|

| Company: | Qingdao Kailite plastic machinery Co., Ltd | ||

| City/State | Qingdao, | Country: |

China

|

| Business Type: | Export - Manufacturer / Trading Company | Established: | NA |

| Member Since: | 2021 | Contact Person | Peter Tai |

SUPPLIER PROFILE

City/State/Country -

Qingdao,

China

Business Type -

Export - Manufacturer / Trading Company

Established -

NA

Member Since -

2021

Contact Person -

Peter Tai