Advertisements

Medical Instruments

| Price: | US$ 1 / Piece |

|---|---|

| Minimum Order: | 1 |

| Payment Terms: | depends( normally: 30% pre-payment, 30% middle-pay |

| Port of Export: |

Product Details

| Model No.: | Brand Name: | Cosmoplat |

|---|

| Certification: | |

|---|---|

| Specification: | medical plastic molding |

Packaging & Delivery

| Packaging: | |

|---|---|

| Delivery/Lead Time: | depends (3-90days even more) |

| Production Capacity: | The mold is a customized product, we can supply it globally, and there is no capacity limit for the |

Product Description

Medical instruments refer to equipment, appliances and other related items used directly or indirectly on the human body. We provide include but are not limited to CT, MAGNETIC Resonance Equipment, B Ultrasound,X-ray Machine, Oxygen Machine, Breathing Machine, Operating Table, Hospital Bed, Stretcher and so on. We are committed enough to meet all your needs.

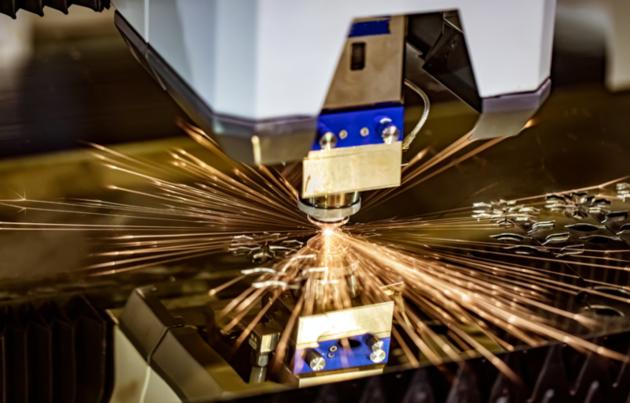

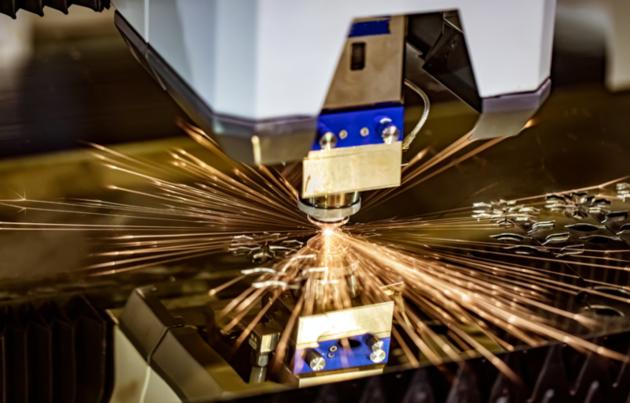

Introduction to Medical Injection Molding

Today,the essential function of medical injection molding is to manufacture medical components or devices that use durable, reliable medical-class materials. The medical plastic injection molding process is cost effective and the best choice for high volume production runs and applications requiring consistency and tight tolerances. Medical injection molding process is also used for the R&D work of medical device prototype in the FDA approval process and laboratory testing.

COSMOPlat is one of the most professional and experienced medical molding companies in China. If you are looking for more details about medical device injection molding, contact us now!

3D Printing and Medical Devices

3D printing goes to the classification of additive manufacturing. Through constructing successive layers of raw material, 3D printing is able to manufacture three-dimensional objects. Each layer is attached by a new layer until the object is finished.

And how 3D printing is applied to medical equipment? With 3D printing technology, the designers is allowed to change their design without the need to configure additional devices or instruments. Bedises, by employing 3D printing , manufacturers are also able to produce equipments that most match the condition of the patients.

Medical Instruments FAQ

What are the benefits of medical device injection molding?

The benefits are as follows:

· Cost-efficiency

· Outstanding accuracy

· Material selection

· Durability

· Contaminant resistance

What medical equipment can be 3D-printed?

Surgical instruments such as forceps, retractors, medical clamps, needle drivers, hemostats and scalpel handles.

How does the medical industry use 3D printing?

3D printing is now tested to manufacture personalized prosthetics and orthotics and other customized casts made of light plastic. It can greatly reduce the production costs of certain medical instruments.

COSMOPlat is a professional china mold maker, we provide 3d printing and medical devices, medical device molding, medical equipment 3d printing, 3d printing in healthcare ppt, medical plastic molding, 3d printing technology in healthcare, die casting service and etc. Want to know more? Please contact us.

|

SUPPLIER PROFILE

|

|||

|---|---|---|---|

| Company: | Haier Digital Technology (Qingdao) Co., Ltd. | ||

| City/State | Qingdao, Shandong | Country: |

China

|

| Business Type: | Export - Manufacturer / Trading Company | Established: | 2018 |

| Member Since: | 2021 | Contact Person | Wang Yokini |

SUPPLIER PROFILE

City/State/Country -

Qingdao, Shandong

China

Business Type -

Export - Manufacturer / Trading Company

Established -

2018

Member Since -

2021

Contact Person -

Wang Yokini