Advertisements

Industrial ultrasound cake cutting machine

| Price: | US$ 11129 / Set |

|---|---|

| Minimum Order: | 1 |

| Payment Terms: | FOB |

| Port of Export: | Shanghai Qingdao Tianjin |

Product Details

| Model No.: | HDMS-LSX600P | Brand Name: | Meishun |

|---|

| Certification: | |

|---|---|

| Specification: |

Dimensions: L1545*W900*H 1415 mm Voltage: 220V/50Hz ý 10% Product Shape: Rectangular; Loaf & Roll Rated Power: 1.2 KW Product Type: Ambient; Frozen; Hard Knife Width: 300 mm *2 Product Size: 60*40 cm; Knife Height: 127 mm Cutting Speed: up to 60 cuts per minute |

Packaging & Delivery

| Packaging: | Plywood packaging |

|---|---|

| Delivery/Lead Time: | 20 days for ready goods |

| Production Capacity: | 50 |

Product Description

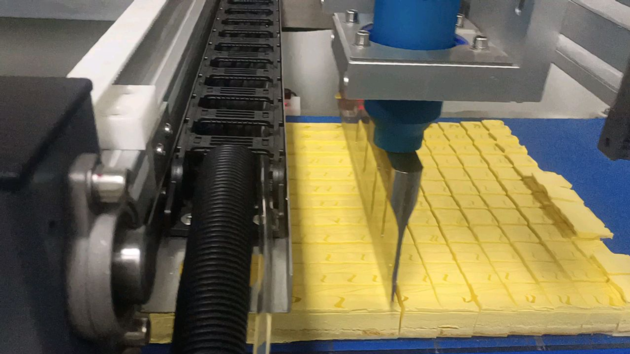

If you have demand, you can contact me at any time. We will reply you as soon as possible. This is our contact information: +86 16632060421. Welcome to inquire. The ultrasonic food cutting assembly line is completely different from the traditional cutting assembly line. The traditional cutting uses a knife with a sharp edge to press the food to be cut. The pressure is concentrated at the knife edge, and the pressure is very large. Therefore, the material is pulled apart by a strong pressure. The cutting effect on sticky, soft and elastic materials is not good. And the cutting surface is not complete and smooth at the same time. The ultrasonic cutting assembly line uses ultrasonic energy for cutting and processing equipment to achieve the purpose of cutting food. The ultrasonic vibration of the cutting knife makes the friction resistance very small. It does not require a sharp blade and great pressure when cutting. and will not cause the edge collapse and damage of the cutting material. The cutting surface is smooth and neat, and the cut material is not easy to stick to the blade. For food that cannot be cut by traditional cutting machine, it can also complete cutting work with high standards, especially for frozen, viscous and elastic materials. The machine is designed as a servo driven conveyor belt through system, servo blade actuator, ultrasonic cutting system, interlocking safety protection device, and it is easy to clean. Realizing automatic and continuous cutting. The ultrasonic food cutting line can be used independently or connected to the production line. The cutting speed is fast and the degree of automation is high, It is applicable to a variety of scenarios, such as large food processing plants, central factories, chain bakeries, etc.

Advantages of ultrasonic food cutting assembly line:

1. Ultrasonic cutting reduces friction, with fine incision, no debris, no deformation, no cross color, and smooth and beautiful cutting surface.

2. The machine adopts titanium alloy blade, which is completely inert and durable. It is not easy to stick the blade during cutting, and is suitable for cutting sticky and elastic food, multi-layer sandwich cake, etc.

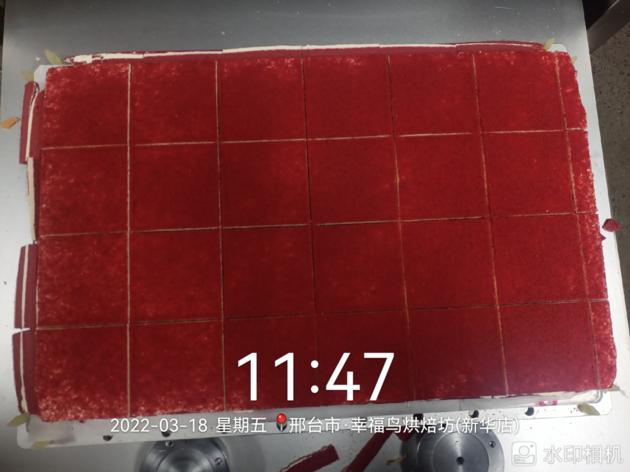

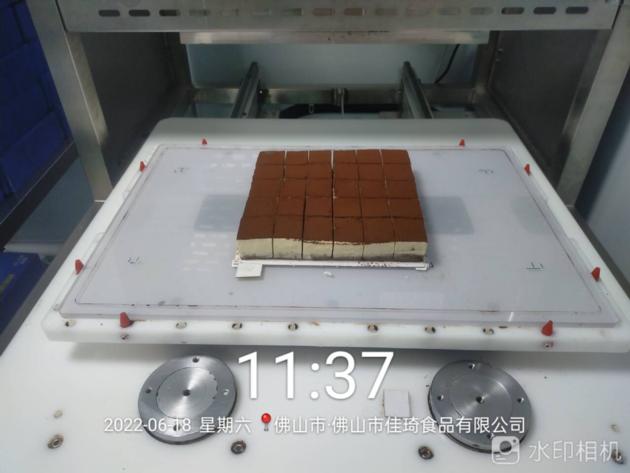

3. The cutting range is wide, such as mousse cake, Swiss roll, dough, egg tarts, candy, cheese, butter, sandwiches, pizza, bread, biscuits, chocolate, pies, nougat, sesame sugar, Shaqima, Napoleon, thousand layer cake, pudding cake, brownie, rice cake, jujube cake nut food, baked food, various cakes, soft, crisp, sticky food, etc.

4. There are many choices for cutting mode, such as sheet, strip, roll, block, etc.

5. The machine can realize continuous cutting, fast cutting speed, automatic and intelligent operation, and save labor costs.

6. The machine can be used as a stand-alone or embedded solution, with dual choices.

7. The machine is stable in working condition, suitable for long time continuous work, and has high working efficiency.

8. In the process of machine cutting, the food to be cut is moved in parallel or in parallel order, which reduces the downtime.

9. Siemens servo control, high durability, low failure rate, accurate positioning, and minimal error in the cutting process.

10. The machine is equipped with sensors to position and cut the products to improve production efficiency.

11. The machine can match a variety of specifications, which can be customized according to customer requirements.

FAQ:

1.About product quality

Our machines have obtained CE certificates, and other certificates can be provided according to customer requirements.

2.Manufacturing time

Fast delivery, manufacturing time for regular orders is 7-10 days; If it is customized, it will need about 20 days, as appropriate.

3.Transport

Machines are usually transported by sea, train or air, and we would like to help our customers find the best way to transport them.

4.About after-sales service

Fast after-sales response, professional technical support, the machine comes with a detailed operation manual. If you have any questions, you can contact us at any time.

5.About warranty

The warranty period is one year, the lifelong maintenance. And we can provide all the accessories you need.

|

SUPPLIER PROFILE

|

|||

|---|---|---|---|

| Company: | Handan City Meishun Machine Co., Ltd | ||

| City/State | Handan, Hebei | Country: |

China

|

| Business Type: | Export - Manufacturer / Trading Company | Established: | 2014 |

| Member Since: | 2022 | Contact Person | HDMS Chang |

SUPPLIER PROFILE

City/State/Country -

Handan, Hebei

China

Business Type -

Export - Manufacturer / Trading Company

Established -

2014

Member Since -

2022

Contact Person -

HDMS Chang