Advertisements

Industrial Mould

| Price: | US$ 10000 / Set |

|---|---|

| Minimum Order: | |

| Payment Terms: | TT |

| Port of Export: |

Product Details

| Model No.: | Brand Name: |

|---|

| Certification: | |

|---|---|

| Specification: | Fan mould |

Packaging & Delivery

| Packaging: | |

|---|---|

| Delivery/Lead Time: | 4 weeks |

| Production Capacity: |

Product Description

Fan mould

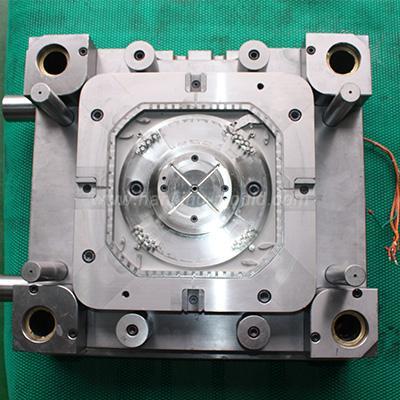

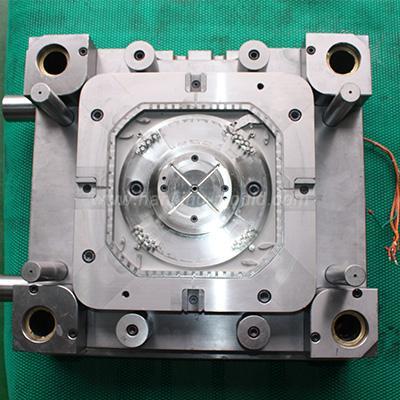

Mould Name: Fan Motor MouldPart Material:PA6 GF30Product Size: 246*246*16.74 MMProduct Description: Motor SuspensionMould Cavity: 1 CavityMould Size: 560*550*660 MMSuitable Injection Machine:Mould Cavity...

Fan Plastic Mold

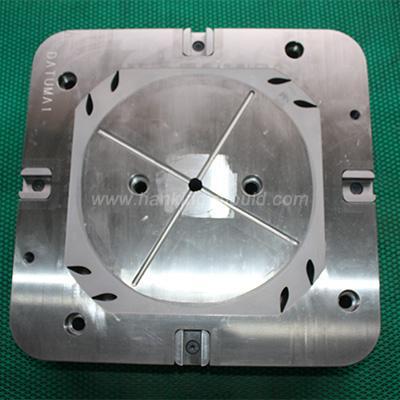

Mould Name: Fan MouldPart Material: PA6 GF30Product Size: 246*246*108.5Product Description: Guide VaneMould Cavity: 1 CavityMould Size: 630*550*630 MMSuitable Injection Machine:Mould Cavity Steel: ASSAB 8407...

Plastic Mould for Air Guiding Fan

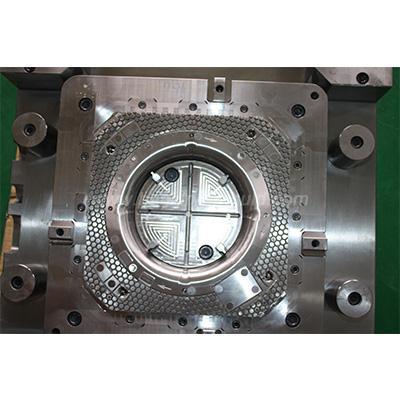

Mould Name: Fan MouldPart Material: PA6 GF30Product Size: 270*270*20 MMProduct Description: Inlet Ring Mould Cavity: 1 CavityMould Size: 650*550*650 MMSuitable Injection Machine:Mould Cavity Steel: ASSAB...

Industrial mould is not a mold technology process, but a type of mold that is distinguished from the purpose of use.

Generally speaking, products produced with industrial molds are used for processing or business operations, such as industrial instruments, valves, fittings, pipes, tools, etc..

What types are moulds classified by structure?

Side plate mould

Pinpoint plate mould

Three plate mould

Reverse gating mould

Stack Mould

When we classified by mold steel, they are soft mould, prehardening mould, hardened mould, stainless mould, aluminum mould, beryllium copper mold. We determine the type of mold to be made according to the needs of our customers.

What's the industrial mould hardening method?

Normally there are heat treatment, nitriding treatment, chrome plating, nickel plating.

There are cold runners and hot runners from the type of runner.

Which runner is used depends on the cost of the raw material and total output of the product, under the premise of ensuring quality, the mold development cost is reduced as much as possible, thereby reducing the research and development cost of the entire project and improve the competitiveness of the product.

HANKING has extensive experience and expertise in the design and manufacture of custom industrial molds, enabling HANKING to develop practical, production-based solutions for many years of practice.And they have industrial molds for sale.

We can make small batches of production for customers as well as validation production at all stages and provide FAI, CTF, CPK report.

Mould trial report, mold temperature monitoring records is able to help customers quickly start the production after receiving the molds.

Related News

How to Make Good Plastic Part?

Shape-Following Cooling Can Greatly Improve The Production Efficiency Of Injection Molds

Injection Mold Building Process

Global Precision Mould Material Conference

Manufacturing of Dies for Automobile Covering Parts in China

Development Trend of Mould Industry in China

HanKing Mould Enginering Ltd. started the business in the year of 1996 as a injection mold maker company in the line of mold making and injection molding in Longgang, Shenzhen, China. With continuous developments and progresses, we have become a professional Chinese plastic injection tooling company, offering custom plastic injection molding service, plastic molding manufacturing and other mould making services.

|

SUPPLIER PROFILE

|

|||

|---|---|---|---|

| Company: | HANKING MOULD ENGINEERING LTD. | ||

| City/State | Shenzhen, guangdong | Country: |

China

|

| Business Type: | Export - Manufacturer / Trading Company | Established: | 2011 |

| Member Since: | 2020 | Contact Person | Yoyo Tang |

SUPPLIER PROFILE

City/State/Country -

Shenzhen, guangdong

China

Business Type -

Export - Manufacturer / Trading Company

Established -

2011

Member Since -

2020

Contact Person -

Yoyo Tang