Advertisements

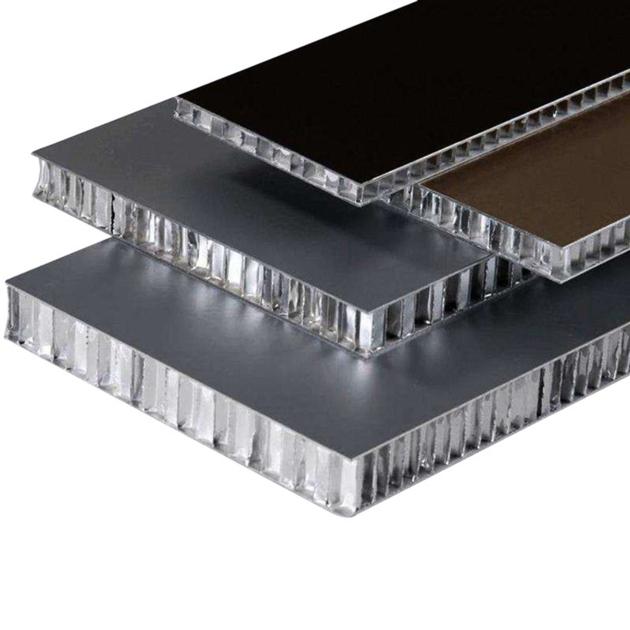

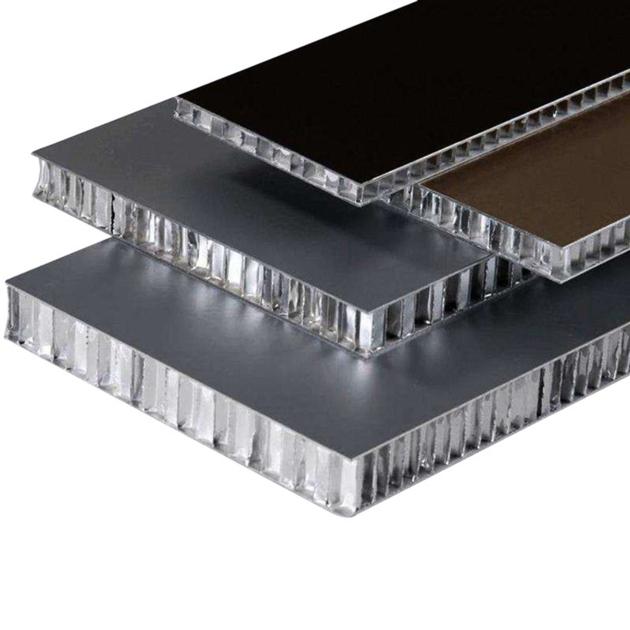

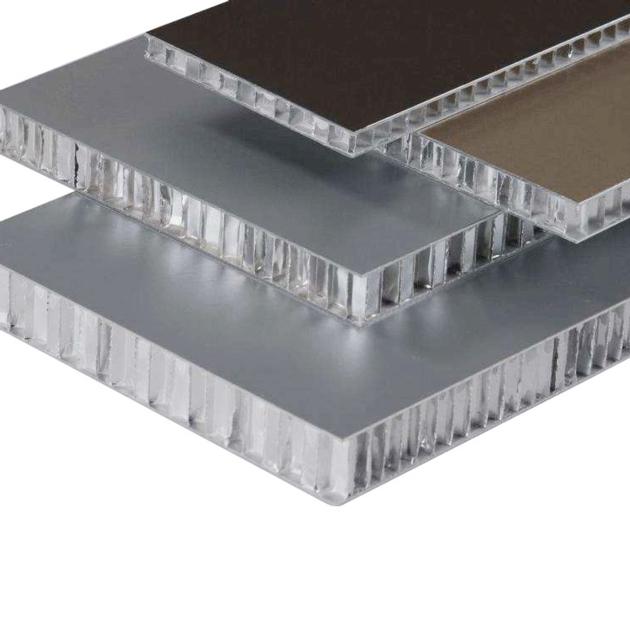

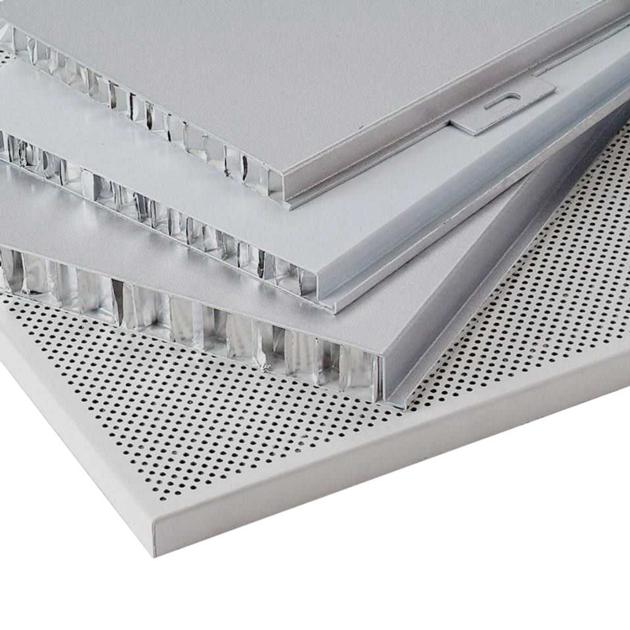

Honeycomb panels for new building floor

| Price: | US$ 30 |

|---|---|

| Minimum Order: | 20 |

| Payment Terms: | T/T |

| Port of Export: | Tianjin |

Product Details

| Model No.: | Brand Name: | MAYNOWEI |

|---|

| Certification: | ISO9001 |

|---|---|

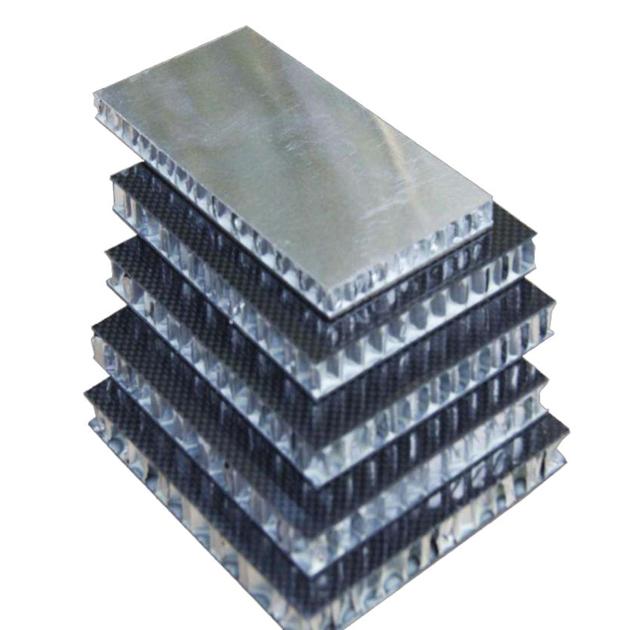

| Specification: | Aluminum honeycomb plate introduces that the core material adopts hexagonal 3003 aluminum honeycomb core, the thickness of aluminum foil is 0.04 × 0.06mm, the side length is 5 × 6mm, the roll forming technology is used to complete the molding of positive and back skin, the automatic machine equipment is folded, and the positive and back epidermis are tightly occlusal at the installation edge. The whole processing process is completed in modern factory, using hot pressing technology, because of the high heat conduction value between aluminum skin and honeycomb, the thermal expansion and cold shrinkage of inner and outer aluminum skin are synchronized; there are small holes in honeycomb aluminum skin, so that the gas in the plate can flow freely; the sliding mounting buckle system will not cause structural deformation when thermal expansion and cold shrinkage, so it can ensure very high smoothness. Using adhesive: two-component polyamine ester high temperature curing adhesive, using automatic honeycomb plate |

Packaging & Delivery

| Packaging: | PE film |

|---|---|

| Delivery/Lead Time: | 3-30 |

| Production Capacity: |

Product Description

Aluminum honeycomb plate introduces that the core material adopts hexagonal 3003 aluminum honeycomb core, the thickness of aluminum foil is 0.04 × 0.06mm, the side length is 5 × 6mm, the roll forming technology is used to complete the molding of positive and back skin, the automatic machine equipment is folded, and the positive and back epidermis are tightly occlusal at the installation edge. The whole processing process is completed in modern factory, using hot pressing technology, because of the high heat conduction value between aluminum skin and honeycomb, the thermal expansion and cold shrinkage of inner and outer aluminum skin are synchronized; there are small holes in honeycomb aluminum skin, so that the gas in the plate can flow freely; the sliding mounting buckle system will not cause structural deformation when thermal expansion and cold shrinkage, so it can ensure very high smoothness. Using adhesive: two-component polyamine ester high temperature curing adhesive, using automatic honeycomb plate composite production equipment through pressure high temperature composite, to overcome the brittleness of the previous honeycomb plate adhesive layer. The inner layer is a special hexagonal aluminum honeycomb, which is composed of aluminum alloy with hardness up to H19. As the core plate attached to the sandwich structure, the inner layer is subjected to pressure in tangential direction. These dense honeycomb, like many small I-shaped beams, can bear the pressure from the direction of the panel, make the force of the plate uniform, and ensure that the panel can still maintain a high smoothness in a large area. Installation using both sides of the installation, no mechanical damage. The sliding installation buckle system allows thermal expansion and cold shrinkage, and the stop buckle at the bottom of the plate will control the expansion direction of the board. 25 mm hidden adhesive seam system is beautiful and self-cleaning. After the completion of the box honeycomb plate, the inner and outer plates and the honeycomb structure form a whole. In addition, the hollow honeycomb can also greatly reduce the thermal expansion of the plate. Because of its high wind pressure resistance, shock absorption, sound insulation, heat preservation, flame retardancy and high specific strength, honeycomb materials have excellent properties such as high wind pressure, shock absorption, sound insulation, heat preservation, flame retardancy and high specific strength. Foreign countries have been used in various fields of civil affairs in 1960's, and have developed rapidly. In recent years, cellular technology has only been applied in various fields of civil industry in our country. Aluminum honeycomb curtain wall has been widely used in exterior wall decoration of high-rise buildings because of its light weight, high strength, high stiffness and so on. The total thickness is 15 mm, and the aluminum honeycomb plate with 1.0mm thickness is only 6kg/. The weight of the honeycomb board with the same stiffness is only 1 × 5 of the aluminum veneer and 1: 10 of the steel plate. The connected aluminum honeycomb core is like countless I-shaped steel, the core layer is fixed in the whole plate surface, which makes the plate more stable, and its wind pressure resistance is much higher than that of the aluminum veneer and aluminum veneer, and has the characteristics of not easy deformation and good flatness, even if the size of the honeycomb board is very large. It can also achieve very high flatness and is the first choice of lightweight materials in the construction industry.

|

SUPPLIER PROFILE

|

|||

|---|---|---|---|

| Company: | Tianjin Maynowei New material Technology Co., Ltd | ||

| City/State | Tianjin, Tianjin | Country: |

China

|

| Business Type: | Export - Manufacturer / Trading Company | Established: | 2019 |

| Member Since: | 2020 | Contact Person | Laura Hu |

SUPPLIER PROFILE

City/State/Country -

Tianjin, Tianjin

China

Business Type -

Export - Manufacturer / Trading Company

Established -

2019

Member Since -

2020

Contact Person -

Laura Hu