Advertisements

High technology Fully automatic continuous waste tyre pyrolysis plant

| Price: | US$ 220000 |

|---|---|

| Minimum Order: | 1 |

| Payment Terms: | T/T, L/D |

| Port of Export: | Qingdao, Shanghai,Lianyungang |

Product Details

| Model No.: | DY-C-20/30/50 | Brand Name: | DOING |

|---|

| Certification: | CE, ISO |

|---|---|

| Specification: |

Model:DY-C-20/30/50

Delivery:40FR+40HQ Weight:25-45T Power:35-80kw Size:30*20*7m |

Packaging & Delivery

| Packaging: | 40FR+40HQ |

|---|---|

| Delivery/Lead Time: | 30 |

| Production Capacity: | 20 per month |

Product Description

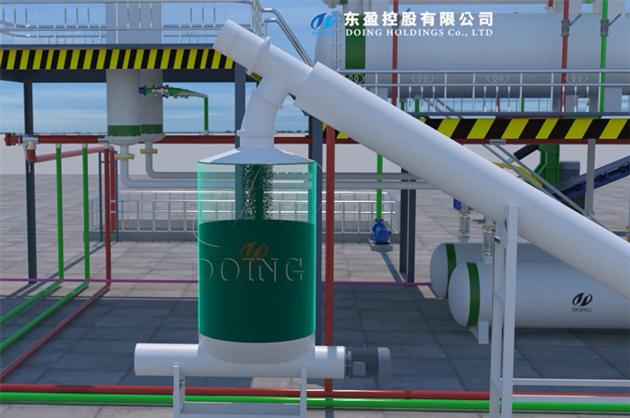

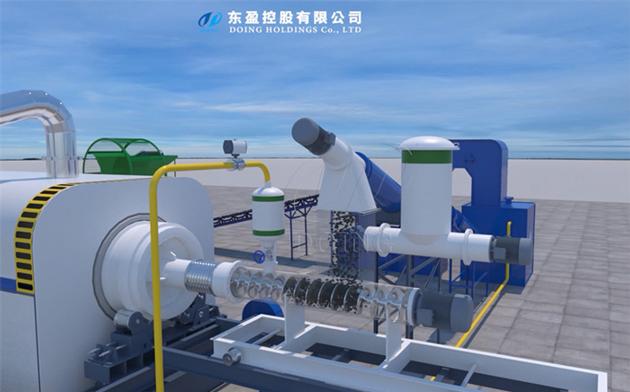

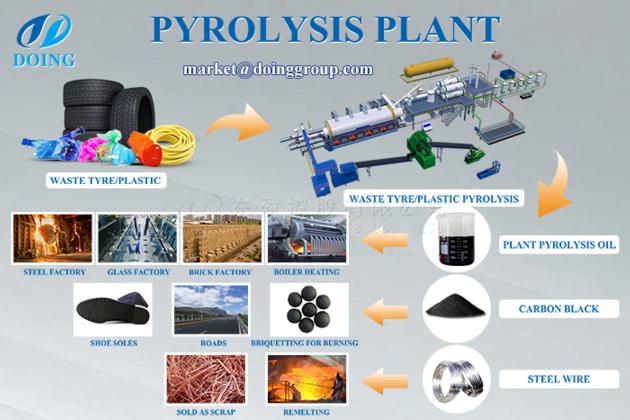

Fully automatic continuous waste tyre pyrolysis plant includes waste tyre pretreatment system, continuous pyrolysis system with continuous feeding and discharge system controled by PLC system. The main part is the continuous pyrolysis system. Continuous waste tyre pyrolysis plant is for processing waste tyres into fuel oil and carbon black for recycle use. Due to continuous feeding and discharge system, the continuous waste tyre pyrolysis plant can keep working without stop, thus to save energy and time. Also PLC control system makes much less labour cost.

MAIN FEATURES

1.Fully automatic with low labour cost

Our conitnuous waste tyre pyrolysis plant is controled by PLC system with automatic feeding and discharge system, which only need 1-2 worker for operating the PLC or computer is ok.

2. Precise calculation system to ensure full pyrolysis and high oil yield

The continuous waste tire pyrolysis plant is equipped with an accurate calculation system to ensure that the tire is fully cracked in the reactor, and fully converted into oil and gas, thus the oil yield is high.

3.Big capacity with small land occupy size

Also due to continuous feeding and discharge system, and unique mutiple reactor design, our fully automatic continuous waste tyre pyrolysis plant can process at least 10 tons waste tires per day, up to 50T/D. And it takes up very little space, saving customers space costs and increasing profits.

4.Internal rotating for conitnuous operation

For external rotating system, you have to change the sealing material every three days, thus cannot achieve the real sense of continuous process. But our continuous waste tyre pyrolysis reactor adopts internal rotating method, which no need to worry about the sealing of the external rotating system.

5.Unique sealed feed and slag discharge system to ensure safety and environmental protection

The feed and slag discharge system of continuous waste tire pyrolysis plant adopts unique seal design, which can effectively prevent cracked oil and gas from leaking through the feed inlet and slag discharge port, ensuring production safety.

If you’re facing waste tires pollution or disposal problems, and be badly in need of a processing system, please feel free to contact us and and warmly welcome to visit our factory. We DOING Company are always ready to provide you the best solution.

*

*

Whatsapp/WeChat:+8613526692320

*

|

SUPPLIER PROFILE

|

|||

|---|---|---|---|

| Company: | Henan DOING | ||

| City/State | Zhengzhou City, Henan | Country: |

China

|

| Business Type: | Export - Manufacturer / Trading Company | Established: | 2011 |

| Member Since: | 2020 | Contact Person | pyrolysis plant |

SUPPLIER PROFILE

City/State/Country -

Zhengzhou City, Henan

China

Business Type -

Export - Manufacturer / Trading Company

Established -

2011

Member Since -

2020

Contact Person -

pyrolysis plant