Advertisements

Copper clad aluminium equipment

| Price: | Contact for latest price |

|---|---|

| Minimum Order: | |

| Payment Terms: | N/A |

| Port of Export: |

Product Details

| Model No.: | Brand Name: |

|---|

| Certification: | |

|---|---|

| Specification: | N/A |

Packaging & Delivery

| Packaging: | |

|---|---|

| Delivery/Lead Time: | |

| Production Capacity: |

Product Description

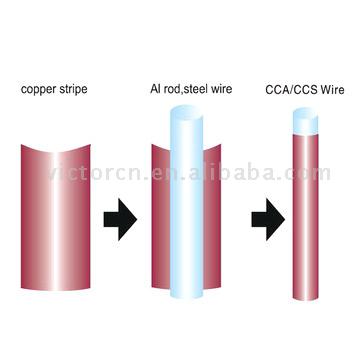

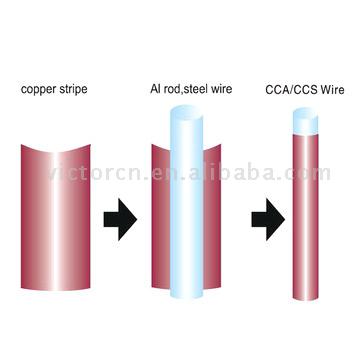

Victor Machinery Co. is specializing in copper clad aluminum wire production line. It is use cooper belt and aluminum wire as material; and can cover the copper on the aluminum wire surface.

So this wire can be used to exchange the copper wire. And its weight is less; and has good advantage of conductivity; and it is widely used on the electrical cable. All of our technologies are introduced from Japan.

Features:

1) Material of aluminum: diameter 8.5mm

2) Material of copper: density: 99.97%, width 31.2mm, thickness: 0.38mm

3) Finished wire with diameter: 10mm

4) Production capacity: 6 meters/minutes

we are the expert of the copper clad aluminium wire and cable making machine in China, we can supply the complete making line for copper clad aluminium wire. We are a company that professionally to manufacture wires and cables making machinery, Main components of our products have sold

well in southeastern Asia, Mainland China and Middle East.

The machine equipment:

1.Copper clad aluminum wire is produced with the production process of cladding welding-drawing method, by cladding polished copper strip concentrically on the outer surface of the aluminum core, via several times of drawing and heat treatment, to meet customers' technical requirement on line diameter, mechanical property and electrical property, Aluminum rod pre-drawing machine ------Pre-drawing the aluminum rod to¥Õ8.5mm on the¥Õ1200 drawing machine

2.Cleaning ------put the pre-drawing the aluminum rod in the No.1 flume where there is 4~7% NaOH, then put it into the NO.2 water flume , then put it into the NO.3 flowing water flume and cleaning and airing .

3.Aluminum rod releaser

4.Copper strip releaser

5.Copper strip cleaning and drying------clean the copper strip in the small water box where there 5~10%scour , and filter the water , and wipe the water

6.Aluminum rod and copper strip brushing , two sets of blower for collecting the copper and aluminum scraps

7.Arc welding clad machine , by cladding polished copper strip concentrically on the outer surface of the aluminum core;

8.Winding

Remark : Draw the wire in the same day after u weld the Copper clad aluminum rod .

9. Single head drawing ------Roll the end of the CCA wire, drill through the 1~3 molds , and drawing the wire on the¥Õ1200 , ¥Õ1000, ¥Õ800 on the drawing machine one by one.

10.Winding and inspecting ------ Inspecting and removing the vice wire , and welding by the cold welder machine .

11.Products ------ winding the products ,and packing it.

|

SUPPLIER PROFILE

|

|||

|---|---|---|---|

| Company: | Jiang su Victor machinery co.,ltd | ||

| City/State | zhangjiagang, Jiang su | Country: |

China

|

| Business Type: | Export - Manufacturer / Trading Company | Established: | 1958 |

| Member Since: | 2006 | Contact Person | Ding ding |

SUPPLIER PROFILE

City/State/Country -

zhangjiagang, Jiang su

China

Business Type -

Export - Manufacturer / Trading Company

Established -

1958

Member Since -

2006

Contact Person -

Ding ding