Advertisements

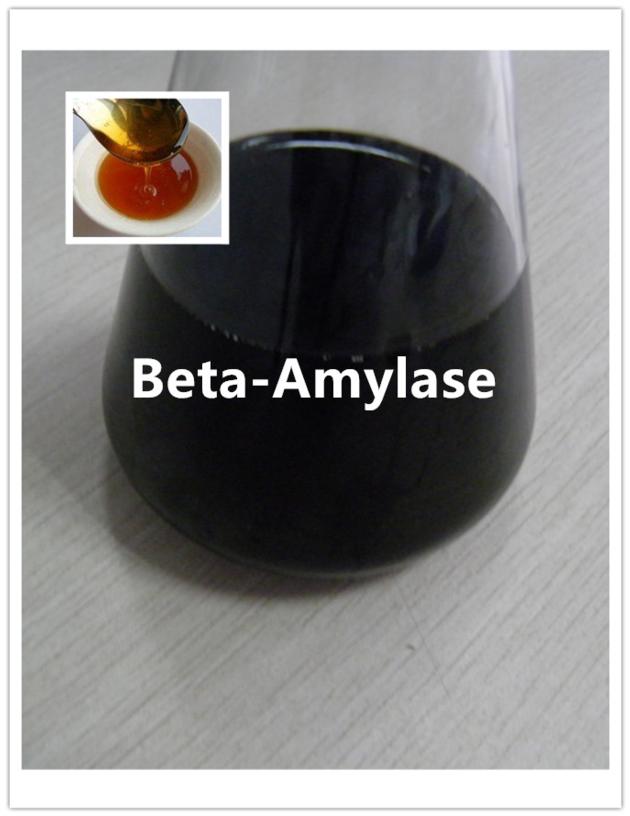

Beta-Amylase

| Price: | US$ 12.98 |

|---|---|

| Minimum Order: | 1kg |

| Payment Terms: | 100%TT in advance |

| Port of Export: | Qingdao port |

Product Details

| Model No.: | Brand Name: | Co-Suppliers |

|---|

| Certification: | ISO9001 |

|---|---|

| Specification: |

Beta-Amylase is a kind of exo-amylase. It begins at the non-reducing end of the liquefaction starch and hydrolyze them in turn against the maltose unit and react Walden inversion. So the product become to β maltose from alpha type. This enzyme can’t hydrolyze α-1,6-glucosidic link of starch . Before 1,6 link 2~3 glucoase residue stop as starch decomposition .Basically no glucose produce for maltose. Properties: 1. Temperature : It is stable above 70«C, optimum 55-60«C 2. pH : Effective Range : 3.0-6.5 , optimum range 5.0-5.6 3. Effect of Metal Ion on Enzyme activity: Ca2+, Mg2+ activate the enzyme , Cu2+,Hg2+, Fe3+ and oxidizing agent have the inhibition on the enzyme . Specification: Liquid type; Appearance: dark brown liquid ; Acitivity:700000u/ml ; Liquid Enzyme pH( 25«C): 4.0-6.0, Specific Gravity: ≤1.25 g/ml 2. Unit definition One β-amylase unit is defined as the amount of enzyme which produce maltose amount per hour from 1.10% stach solutions at 60 «C,Ph5.5, express in u/g/ml. |

Packaging & Delivery

| Packaging: | 25kg/ drum |

|---|---|

| Delivery/Lead Time: | Within 2 weeks after payment |

| Production Capacity: | 50000Tons per Month |

Product Description

Application Guide: The optimum saccharification conditions lie on saccharification time ,Ph ,temperature, substrate concentration and enzyme dosage . so the application plant should decide the optimum technological conditions according to their conditions . the recommended usage methods are as follows:

1. In the manufacture of maltose syrup and beer brewing ,0.1-0.3L/t dry basis ,the optimum saccharification 0.5-30 hours.

2. In the manufacture of high maltose syrup (>70%) , saccharification stage need to together with pullulanase , the recommended methods : β- Amylase 0.5-1.0L/t dry basis , pullulanase 0.5-1.0L/t dry basis ( base on 1000 u/ml) , saccharifying for 24 hours.

3. In the manufacture of super high maltose syrup (>90%) , saccharification stage need to together with pullulanase , the recommended methods : β- Amylase 1.5-2.0L/t dry basis, pullulanase 1.5-2.8L/t dry basis ( base on 1000 u/ml) , saccharifying for 24 hours and adding Maltotriose, saccharifying for 24 hours again.

|

SUPPLIER PROFILE

|

|||

|---|---|---|---|

| Company: | Co-suppliers Limited | ||

| City/State | Shanghai, Shanghai | Country: |

China

|

| Business Type: | Export - Manufacturer / Trading Company | Established: | 2010 |

| Member Since: | 2019 | Contact Person | Vivie Chang |

SUPPLIER PROFILE

City/State/Country -

Shanghai, Shanghai

China

Business Type -

Export - Manufacturer / Trading Company

Established -

2010

Member Since -

2019

Contact Person -

Vivie Chang