Advertisements

Automatic working tapioca starch extraction machine full stainless steel tapioca starch production e

| Price: | US$ 100000 / Set |

|---|---|

| Minimum Order: | 1 set |

| Payment Terms: | LC, T/T, D/P, D/A, O/A etc. |

| Port of Export: | Qiondao, Shanghai, Ningbo |

Product Details

| Model No.: | Brand Name: | DOING |

|---|

| Certification: | |

|---|---|

| Specification: |

Condition:

New, New Place of Origin: Henan, China Brand Name: DOING Video outgoing-inspection: Provided Machinery Test Report: Provided Marketing Type: New Product 2020 Warranty of core components: 1 Year Core Components: PLC, Bearing, Pump Warranty: 1 Year, 12 Months After-sales Service Provided: Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service Local Service Location: Nigeria Applicable Industries: Manufacturing Plant, Cassava starch processing line Showroom Location: Nigeria Name: Cassava starch processing plant Color: depends your request Material: stainless or carbon steel Voltage: 380V/50HZ Advantage: Saving energy Size: 47*52*118 cm Machine type: Complete Set Weight: 1500kg |

Packaging & Delivery

| Packaging: | Automatic wet processing technology cassava starch production line: Standard exporting package |

|---|---|

| Delivery/Lead Time: | |

| Production Capacity: |

Product Description

Cassava starch processing line introduction:

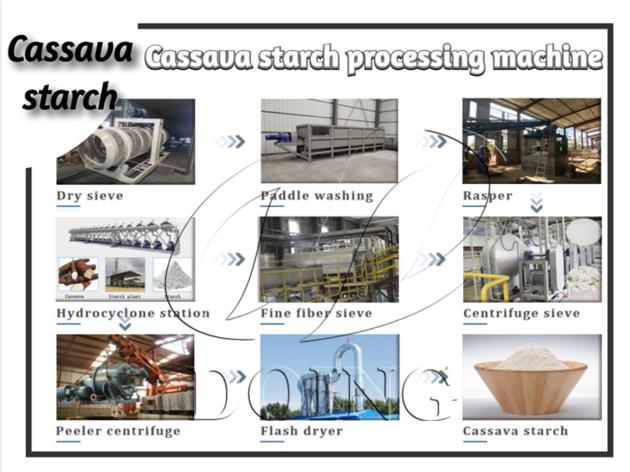

Cassava contains high starch, processing cassava into starch, it has gone through several steps, including cassava cleaning and washing, cassava crushing, starch extraction, filtering and de-sanding, starch concentration and purification, starch dewatering and drying, sieving and packing. These are the main steps of cassava starch processing line. And the following part is to introduce the functions of main machines in cassava starch processing line.

Main Features of Doing Company's cassava starch processing line:

This is the cassava starch production line's technology analysis from Doing Company, as a professional cassava processing line machines manufacture and supplier, Doing Company will give you the reliable cassava starch production technical support. The machines for cassava starch processing line from Doing Machinery offered main include: dry sieve, paddle washer, cassava cutting machine, rasper, centrifuge sieve, fine fiber sieve, desander, hydrocyclone, disc separator, peeler centrifuge, flash dryer, cassava starch sieving machine, automatic packing machine.

Doing Company designed cassava starch processing line is full sealing processing, can guarantee the starch during processing no oxidized, to make sure the produced starch is whiteness, high quality. In the automatic cassava starch production line, from cassava processing to final starch drying totally just 10-15 minutes.

Detailed Images

Cleaning parts of cassava starch processing line:

In this part, dry sieve is first used in impurities pre-removal for starch production. In other words, it used to remove some impurities attached on the surface of cassava. And the next is to use paddle washing equipment to wash the raw materials. It adopts countercurrent washing principle, so the raw materials are washed clean.

Crushing part of cassava starch processing line:

The cutting equipment is used for cutting cassavas into small pieces, 3-5cm, for further production. It consists of foundation, main frame, cutters, ,motor and drive system. Next, these small pieces are grinded by rasper. The equipment with high speed has high efficient and high starch extraction rate.

Starch extraction part of cassava starch processing line:

After that, those small pieces become a kind of mash. Then centrifuge sieve is used for the production of starch from the materials, remove fiber from starch slurry. The equipment with automatic front and back washing system guarantee good screen penetration and high-efficiency operation. Then fine fiber sieve fatherly separates small fiber from starch slurry according to its own gravity and low centrifugal force function by screen mesh inside the drum. The next step is to separate protein, cell liquid out of starch milk, two equipments are used to separate them. One is disc separator. It is one kind of settling centrifuge, which use centrifugal force to accelerate separating process. It can be used for enrichment and purification of starch slurry.

The other is hydrocyclone station. The cyclone separation system includes concentrating, recovering and washing. At this time, a kind of pure starch milk is produced.

Dewatering and drying system of cassava starch processing line:

Peeler centrifuge is used for the starch dewatering. It is a solid-liquid separation equipment which adopts continuous operation and intermittent discharging. The final starch water content is 38%-42%. Next, flash dryer is applied to Tapioca drying. It adopts negative pressure to control the loss of starch and purifies the working environment.

The last step is to sieve starch and the final product is packed by packing equipment.

In brief, Henan doing company will provide a set of high-quality product and after-sale service . our company also has professional installation team with rich experience and guarantees the stable running of projects.

Whatsapp: +86 135 2661 5783

Email:*

|

SUPPLIER PROFILE

|

|||

|---|---|---|---|

| Company: | Henan Doing Mechanical Equipment Co., Ltd | ||

| City/State | Zhengzhou, Henan | Country: |

China

|

| Business Type: | Export - Manufacturer / Trading Company | Established: | 2013 |

| Member Since: | 2018 | Contact Person | cassava machine |

SUPPLIER PROFILE

City/State/Country -

Zhengzhou, Henan

China

Business Type -

Export - Manufacturer / Trading Company

Established -

2013

Member Since -

2018

Contact Person -

cassava machine