Advertisements

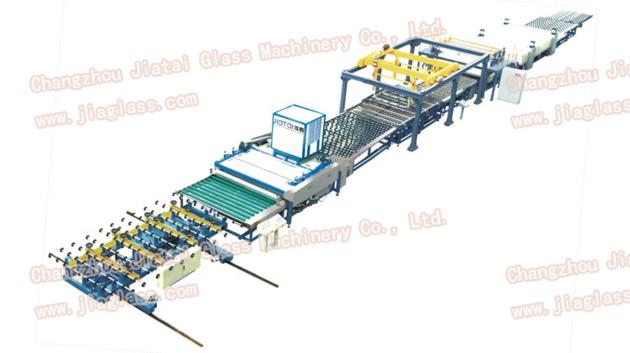

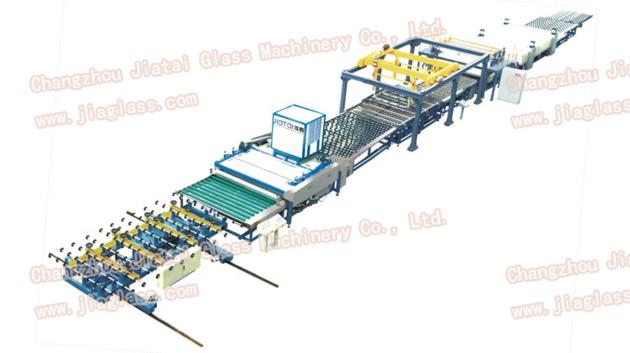

Automatic Laminated Glass Production Line

| Price: | US$ 60000 |

|---|---|

| Minimum Order: | 1 set |

| Payment Terms: | L/C, T/T, Paypal, D/P |

| Port of Export: | Shanghai |

Product Details

| Model No.: | JTL-L | Brand Name: | Jiatai |

|---|

| Certification: | |

|---|---|

| Specification: |

型号Model 最大玻璃尺寸Max Glass Size(mm) 最小玻璃长度Min Glass Length(mm) 厚度Thickness(mm) 功率Power(kw) 生产能力Capacity(m°/8h) JTL-L1660 1600*6000 420 4-40 103.52 400 JTL-L2060 2000*6000 420 4-80 129.18 520 JTL-L2560 2500*6000 420 4-80 153.68 650 JTL-L2580 2500*8000 420 4-80 163.38 800 JTL-L2590 2500*9000 420 4-80 173.68 1000 JTL-L3060 3000*6000 420 4-80 193.47 1300 JTL-L3280 3200*8000 420 4-80 219.27 1400 |

Packaging & Delivery

| Packaging: | Seawothy Packaging |

|---|---|

| Delivery/Lead Time: | 60 days after booked |

| Production Capacity: | 20 sets per month |

Product Description

The full automatic laminated glass production line consists of automatic loading machine,washing and drying machine, transition conveying machine(Ⅰ.Ⅱ.Ⅲ),automatic positioning station, automatic suction hanger, assembling table, PVB film unwinding machine, pre-pressing machine, hydraulic tilting table, and autoclave. Outstanding technique features are as following: 1.The solid and efficient intelligent control system: the whole line is centralized controlled by indusstrial computer assisted in PLC and monitor sdisplay/operation. The design is reasonable with a high degree of automation and easy operation.

2.The whole line is strictly in accordance with the safety regulations and energy saving standards to design and produce, and we can specifically design the desired machines to meet the most stringent requirements of customers from all of the world.

3.Software programs developed all by ourselves cansatisfy any ranges of glass types and sizes for processing, and glass sheets are guaranteed to accelerate or decelerate smoothly in each period of high-speed transmission without any collisions or scratch for good convergence.

4.Automatic loading machine has different demand such as single/double side(s) and single/double/multi working station(s) to load the glass sheets into the working line.

5.Glass Cleaning&Drying machine focuses on appropriate design and convenient operation. Top section including top brushes, rubber rollers and air knives can be adjusted automatically or manually according to the thickness of glass to be processed, and the maximum height can reach 400mm.

6.Automatic pre-positioning machine can achieve glass transmission and accurate lateral positioning through the conveying roller, and longitudinal positioning can be achieved through synchronous belt transmission. After the accurate positioning, the glass sheet will be taken by the automatic suction hanger to the assembling station

7.The position of the automatic suction hanger can be set converniently according to the length of the processing glass to ensure the assembling station

8.Extension Assembling Table can extend the working station according to glass size. PVB Film Unwinding Machine can wind/unwinding the film automatically. The maximum capacity is to load 5 rolls.

9.The pre-pressing machine with unique design and high configuration can realize initial lamination of the glass. The heating elements adopt medium-wave infrared(IR) tube heaters which can be adjusted by SCR to realize no-contact rapid alternation, cooperation with PWM system to automatically adjust the heating conditions so that the rays can be perfectly and rapidly absorbed by the film. The main heating zones are equipped with thermal recycling system,prompting to achieve uniform temperature in the furnace. Pre-pressing machine and autoclave both adopt large cylinders to establish the upper pressure way to throughly exhaust air between the two pieces of glass. Space/distance between the two great squeezing rollers of pre-pressing machine and autoclave can be set manually or automatically with monitor displayed.

10.Hydraulic flipping table is covered with rubber wheel, so the glass can be unloaded without damaging the surface of the glass. Supported by two hydraulic cylinders, it can be fliped smoothly and it is easy to operate.

11.Autoclave is controlled by industrial computer assisted with digital control card and diggital display to realize real-time control. Adopting outside wire connecting and unique wind and water circulating cooling systems ensures safety, convenient operation and short working cycle time.

|

SUPPLIER PROFILE

|

|||

|---|---|---|---|

| Company: | Changzhou Jiatai Glass Machinery Co., Ltd. | ||

| City/State | Changzhou, Jiangsu | Country: |

China

|

| Business Type: | Export - Manufacturer / Trading Company | Established: | 2010 |

| Member Since: | 2018 | Contact Person | Wong Jack |

SUPPLIER PROFILE

City/State/Country -

Changzhou, Jiangsu

China

Business Type -

Export - Manufacturer / Trading Company

Established -

2010

Member Since -

2018

Contact Person -

Wong Jack