Advertisements

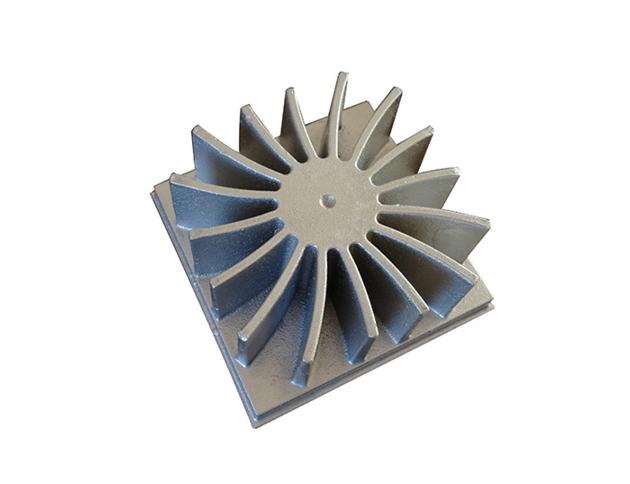

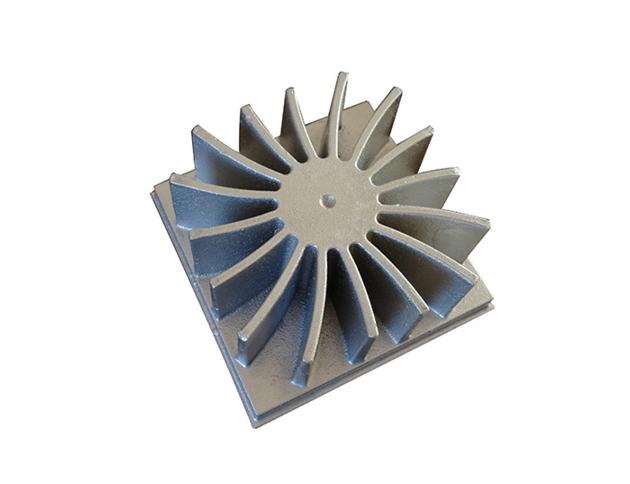

Aluminum Heat Sink

| Price: | US$ 1 / Set |

|---|---|

| Minimum Order: | 1 |

| Payment Terms: | T/T, L/C, D/P |

| Port of Export: | XINGANG |

Product Details

| Model No.: | Brand Name: |

|---|

| Certification: | |

|---|---|

| Specification: |

Die-casting aluminum heat sink: common materials ADC10 and ADC12

Extruded aluminum heat sink: common materials AL6061 and AL6063 |

Packaging & Delivery

| Packaging: | Standard Export Package or as per customers' requirements |

|---|---|

| Delivery/Lead Time: | 15-30 days |

| Production Capacity: | 1500 tons/year |

Product Description

Aluminum Heat Sink

Product Category:

Die-casting aluminum heat sink: common materials ADC10 and ADC12

Extruded aluminum heat sink: common materials AL6061 and AL6063

Stamped aluminum heat sink: common materials 5052、6061、6063

Aluminum alloy heat sink

Aluminum Heat Sink Introduce:

Heat sink is a general term for a series of devices used to conduct and release heat.

Heat sink is a heat dissipation structure composed of a base body of the LED heat sink and a plurality of ridges. Unlike a single slab, the heat sink unit is a U-shaped or V-shaped channel composed of two adjacent ridges and a base.

Heat sink is the most common way to dissipate heat.

custom Aluminum Heat Sink supplier:Botou Junteng Casting Co.,Ltd

Product Feature:

1. Have a certain heat dissipation area

2. Have a certain thermal conductivity

3. Higher thermal emissivity

4. Light weight

5. Easy processing

6. Corrosion-resistant

custom Aluminum Alloy Heat Sink Advantage:

1. Our heat sink is fin type, it is three times higher than traditional heat dissipation efficiency.

2. Lamp housing is integrated with the heat sink, which avoids the drawback that the traditional lamp housing cannot solve the LED heat dissipation.

3. Aluminum heat sink has good oxidation and corrosion resistance without adding any additives. The principle is that once the aluminum encounters oxygen in the air, it will form an oxide film, which is both tough and dense, preventing further corrosion on the bulk material.

1, Aluminum die casting is a process of injection aluminum or aluminum alloy under pressure, which produces parts in high volume at low costs.

2, There are two processes of Aluminum die casting: hot chamber and cold chamber.

3, A complete cycle can vary from one second for small components to minutes for a casting

of large part, making aluminum die casting the fastest technique available for producing precise aluminum & aluminum alloy parts.

4, Any aluminum die casting parts are customized according to the clients' drawing or samples.

More information you can views here

Product Description:

Product Name DIN Aluminum Alloy led heat sink

Material Aluminum or Aluminum Alloy 101, Alloy 1070

Standard DIN ANSI ISO JIS GB BA

Tolerance International Standard -ISO 8062

Production Process 1, Sign Drawing (General clients provide the drawing or samples)

2, Opening the Mould

3, Die Casting ( Aluminum or Aluminum Alloys)

4, Precision Machining (Burring, Lathe, Milling, etc)

5, Surface treatment: Polishing, Electroplating, Sandblasting, Anodizing

6, Inspection and Packing

|

SUPPLIER PROFILE

|

|||

|---|---|---|---|

| Company: | Botou Junteng Casting Co.,Ltd | ||

| City/State | Botou, Hebei | Country: |

China

|

| Business Type: | Export - Manufacturer / Trading Company | Established: | 2014 |

| Member Since: | 2019 | Contact Person | Henry Cao |

SUPPLIER PROFILE

City/State/Country -

Botou, Hebei

China

Business Type -

Export - Manufacturer / Trading Company

Established -

2014

Member Since -

2019

Contact Person -

Henry Cao