Advertisements

2020 newly designed waste tire and plastic pyrolysis machine

| Price: | US$ 56000 / Set |

|---|---|

| Minimum Order: | 1 |

| Payment Terms: | T/T, L/D |

| Port of Export: | Qingdao, shanghai,Lianyungang |

Product Details

| Model No.: | DY-1/6/10/12 | Brand Name: | DOING |

|---|

| Certification: | CE, ISO |

|---|---|

| Specification: |

Function:recycle waste tire, plastic, rubber to oil

Material of reactor:standard Q245R boiler steel |

Packaging & Delivery

| Packaging: | 40FR+40HQ |

|---|---|

| Delivery/Lead Time: | 30 |

| Production Capacity: | 20 per month |

Product Description

Product Description

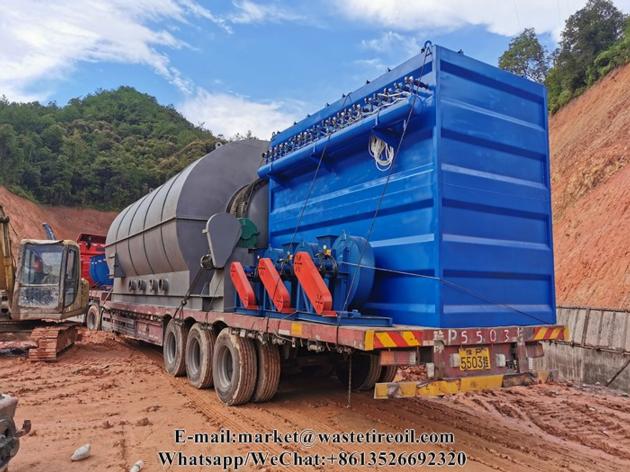

The Introduction of DOING waste tire and plastic pyrolysis machine

Waste tire and plastic pyrolysis machine can turn waste tyre to fuel oil with latest pyrolysis technology. Pyrolysis is the thermal decomposition of materials in the absence of oxygen. In the case of the pyrolysis of rubber tyres, the rubber degrades under high temperatures and long-chain hydrocarbons in rubber are broken down into compounds with shorter carbon chains in the reactor, yielding oil, gas and carbon black.

The Product Application of DOING waste tire and plastic pyrolysis machine

From waste tire and plastic pyrolysis machine, 4 kinds of products can be obtained: fuel oil, carbon black, steel wire, and incondensable gas. Fuel oil is widely used in industries, such as steel factory, heavy oil generator, cement factory, and boiler heating etc. Carbon black can be made into pellets for making new rubber products. Steel wire could be sold to the recycle station or steel mill for remelting. The incondensable gas is recycled to heat the pyrolysis reactor, saving energy.

The Main Advantages of DOING waste tire and plastic pyrolysis machine

1. Safety

The waste tire and plastic pyrolysis machine business is equipped with mature safety devices, such as alarm for over temperature and pressure, auto pressure releasing system, extra gas recycling system and fire fighting device, which will guarantee 100% safety in the tyre to oil recycling process.

2. Energy-saving

By the extra gas recycling system, the gas that can not be condensed will be recycled to the burning room. It can replace the fuel material to heat the reactor, which will reduce additional fuel consumption.

3. Environment friendly

In the dedusting system, three steps (water spray, ceramic ring filter, washing chamber) are used to dedust the extra gas and more than 95% of the dust would be removed. The released gas is pollution-free and can be discharged into the air directly with ISO9001:2008,CE Certificate.

4.Strict requirements for quality

IQC:Incoming quality control,main raw material;

PQC:Process quality control,All the reactor is inspection by X-ray.

Project Case of DOING waste tire and plastic pyrolysis machine

By now we have installed hundreds of waste tire and plastic pyrolysis machine in about 60 countries:

Africa: Nigeria, Congo, Egypt, Uganda;

Europe: Romania, Poland, Italy, Macedonia, Albania, Turkey;

Asia: Malaysia, Pakistan, India, Thailand, Iran, Bangladesh, Lebanon, Jordan;

America: Mexico, Ecuador, Haiti, Guatamala, Aruba, Panama, Jamaica, etc.

Contact Us

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

*

|

SUPPLIER PROFILE

|

|||

|---|---|---|---|

| Company: | Henan DOING | ||

| City/State | Zhengzhou City, Henan | Country: |

China

|

| Business Type: | Export - Manufacturer / Trading Company | Established: | 2011 |

| Member Since: | 2020 | Contact Person | pyrolysis plant |

SUPPLIER PROFILE

City/State/Country -

Zhengzhou City, Henan

China

Business Type -

Export - Manufacturer / Trading Company

Established -

2011

Member Since -

2020

Contact Person -

pyrolysis plant