Advertisements

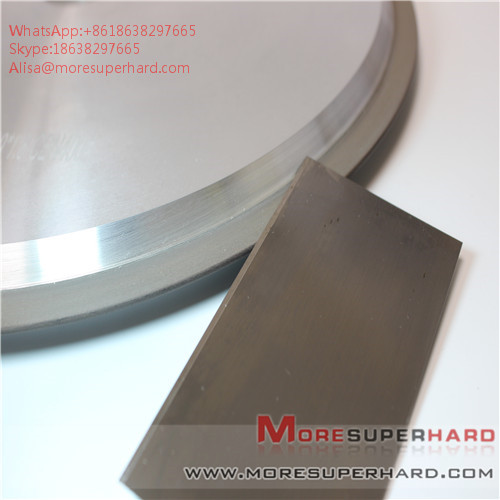

14a1 resin CBN grinding wheel processed stainless steel plate [email protected]

| Price: | US$ 50 / Piece |

|---|---|

| Minimum Order: | 1 piece |

| Payment Terms: | T/T, Western Union, MoneyGram |

| Port of Export: | Shanghai |

Product Details

| Model No.: | 14A1 | Brand Name: | Moresuperhard |

|---|

| Certification: | ISO9001 |

|---|---|

| Specification: |

Packaging:carton box with foam box (Gift package is available)

Terms of payment:T/T, Western Union, MoneyGram Application Industry: Jewelry, Automobile, Aerospace, Oil drilling, Coal mining, Metal processing Certification: ISO 9001:2008 Diamond concentration:25%,50%,75%,100%,etc. Diamond grit:D91,D64,D46,etc. Bonding Agent: Resin Bond Material: Diamond, CBN Brand: More Super Hard Size: D. 25-500mm; T. 5-40mm; H. 10-127mm. Line speed: 35~80 (M/S) Grit: 80#~5000# (D251-D1) Type: Grinding wheel, Polishing wheel, Grooving wheel, Cutting wheel |

Packaging & Delivery

| Packaging: | carton box with foam box (Gift package is available) |

|---|---|

| Delivery/Lead Time: | 7-10 work days |

| Production Capacity: | 1000 piece every week |

Product Description

Introduction to resin diamond grinding wheel

The resin bond diamond wheels are mainly used for grinding tungsten carbide and non-metal materials. Various kinds of dimensions and shapes are available, such as flat shapes, cup shapes and dish shapes, etc.

Production of diamond grinding wheel with resin binder:

Resin as the bond material, metal powder, metal oxide, ordinary abrasive as filler mix to make the binding agent. The abrasive and binder are mixed into the molding material according to the requirements of concentration. The product is formed by hot pressing, curing and subsequent processing

Feature:

1. Diameter: 110-400mm available

2. Diamond grit: #100, #150, #200, #300, #400, or upon your request

3. Thickness: 10mm-32mm, other size is available

4. Hole size: 20mm, 25.4mm, 30mm, or as your request

5. Type: straight wheel, bowl-shaped wheel, cup-shaped wheel, dish- shaped wheel, tapered one side or two sides and so on

Application of resin bond diamond grinding wheel:

Resin-bonded diamond grinding wheel has high hardness, high strength and strong grinding ability. It is mainly used to grind high and hard alloy, non-metal material, hard and brittle hard alloy, non-metal mineral, etc. Such as hard alloy, PCBN, cubic boron nitride integral and welding tool, ceramic, agate, optical glass, semiconductor materials and wear-resistant cast iron, stone, etc.

Advantages Of Resin Diamond Grinding Wheel:

1.High Cutting Efficiency,Good Self-Sharpening, Less Blocking,Reducing The Grinding Burn Occurs When The Phenomenon Of Work

2.Good Flexibility Will Help To Improve The Surface Roughness, Mainly Used For Rough Grinding, Semi-Fine Grinding, Polishing And Other Processes

3.Compared To Conventional Silicon Carbide , Resin Diamond Wheel Has Good Material Removal Rates, Longer Wheel Life And Lower Grinding Costs

4.Resin Bond Diamond Wheels Generally Remove Material Up To Ten Times Faster Than Metal Bond Wheels

Product Feature

1:Easy to dress

2:Good self-sharpening

3:High finishing of work piece

4:Specially for precision grinding and polishing

Production process of Resin bond diamond grinding wheel

1. Mix: the binders and diamond powder are fully stirred and fused in a certain proportion

2. Weighing: weighing according to the volume, ring width and density of the grinding wheel required by the customer

3. Feeding: put mixed diamond powder and binding agent into the grinding tool

4: compression ring (let stand for a period of time to wait for molding)

5: back mould

6: the abrasive layer is air-dried

Cook for 10 hours at 7:670 degrees

8: cooling (prepare the matrix at the same time)

9. Fixed decoration of the who

Packaging & Shipping

Packing Carton, plastic bag,or as your request

Shipping we use DHL,UPS,FEDEX,ect.to ship the goods,or according to the customer's requirement

Delivery time about3-7days, for special time according to your quantity

Our Services

1. Quick Response: Your inquiry will be replied within 24 hours.

2. Competitive Price : Directly from factory to save your money.

3. after-sales warranty : Once there is problem after you received products, you can contact us in time. We will resolve it in short time.

4. Flexibility: Small orders are acceptable for quick delivery and to help you reduce stock cost.

5. OEM service: Custom fabrication according to your drawings ,samples or design

Why choose our product

More SuperHard Products Co., Ltd is dedicated to finding solutions that help our clients in all markets succeed. More SuperHard has been manufacturing high-quality, competitively priced superabrasive diamond and cbn tools that are designed to perform in a wide range of industrial ,such as pcd tools grinding, natural diamond polishing, auto parts processing , thermal spray coated industry, optical glass, semicon and led industry, woodworking tool , cnc tool grinding and roll machining ,others ultral precision industry.

The company production and sales of products covered vitrified bond tools, resin bond tools, metal bond tools, electroplated diamond/cbn tools, vaccum brazed products, cvd diamond tools, polycrystalline diamond (pcd) tools, cubic boron nitride (cbn) tools.our objective is to meet all the customers’ needs and help every customer achieve maximum benefits. more brings in revenue for you, you win, we win!

More SuperHard supplies the wheels for several application mainly:

1.Carbide round tools on cnc machines : flute grinding, gash grinding, end facing, clearance angle and cylindrical grinding .

2. Insert grinding for machines such as: agathon, wendt, haas, waida and ewag.

3.Woodworking saw blade and tools .

4.Hss tools

5.Cutting wheels

Products Range:

1. vitrified bond/resin bond/Metal bond/Electroplated diamond grinding wheel & other diamond tools

2. PCD milling tools, PCD turning tools, PCD drilling tools, PCD engraving tools, PCD/pcbn inserts, PCD/pcbn cutting tools, PCD/pcbn grooving tools, CBN inserts

3. PCD/TSP diamond, CVD diamond tools, large size synthetic diamond, Natural diamond tools, diamond abrasive tools

4. diamond grinding&cutting discs, diamond cutting blade, diamond cup wheel, diamond dressers

5. Roller cutting tools, PDC cutters, PDC drill bits& PDC core bits

6. PCD tool grinder & PCD grinding machine

Our product’s advantages:

1.High grinding efficiency

2.Wonderful edge quality

3.Long service life

4.High polishing efficiency

5.Large Exports

6.Considerable after-sell service

7.Amazing performance

8.Various types and sizes available

9.Direct Factory Manufacturer

10.Backing/substrate material: Aluminum

11.Abrasive layer: diamond

12.Bond: vitrified

13.Excellent cutting edges

14.Reduced cycle times

15.Custom Engineered

If you have any questions, please contact us

Whats App:+8618638297665

Skype:18638297665

*

Tel:18638297665

URL:*

To meet your requirements

In every way, we need the following information.

1. Shape and Dimension of the wheels

2. Grit size (Mesh, refer to Table#1)

3. Concentration

4. Bond (Resinoid, Vitrified, Metallic, Electroplated)

5. Quantity

|

SUPPLIER PROFILE

|

|||

|---|---|---|---|

| Company: | Henan More Super Hard Products Co.,Ltd | ||

| City/State | Zhengzhou, Henan | Country: |

China

|

| Business Type: | Export - Manufacturer / Trading Company | Established: | 2014 |

| Member Since: | 2018 | Contact Person | 'Alisa Zhang' |

SUPPLIER PROFILE

City/State/Country -

Zhengzhou, Henan

China

Business Type -

Export - Manufacturer / Trading Company

Established -

2014

Member Since -

2018

Contact Person -

'Alisa Zhang'