Advertisements

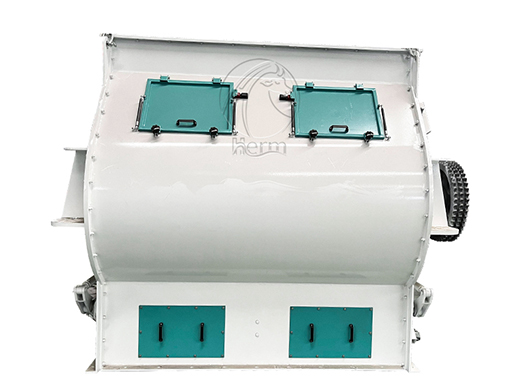

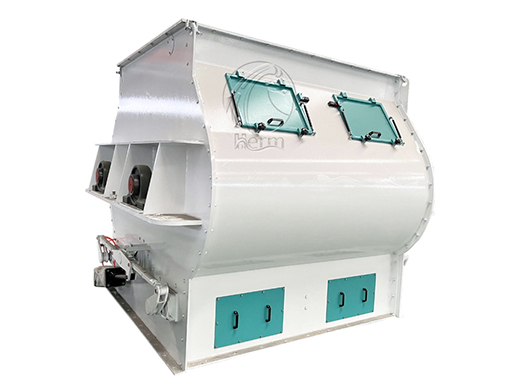

SLHS Shaft Paddle Mixer

| Price: | US$ 2000 / Set |

|---|---|

| Minimum Order: | 1 |

| Payment Terms: | LC、T/T |

| Port of Export: |

Product Details

| Model No.: | Brand Name: | Herm |

|---|

| Certification: | |

|---|---|

| Specification: |

Service: Customized & OEM Cooperation: Factory Directly Brand: Herm¬ Application: mixing the materials for making feed pellet |

Packaging & Delivery

| Packaging: | |

|---|---|

| Delivery/Lead Time: | |

| Production Capacity: |

Product Description

SLHS Shaft Paddle Mixer Introduction Herm Machinery's latest dedicated double-shaft paddle mixer has many advantages. These feed mixers are very gentle on the product, have low energy consumption, high capacity, low space requirements, and flexible filling. It can be equipped with multiple atomizing nozzles for liquid addition, which is convenient for maintenance. Herm Machinery's newest double-shaft paddle mixer consists of paddles on double shafts mounted in a "W" shaped trough. The specific speed of the shaft combined with the overlapping motion and paddle design facilitates fast fluidization and ensures excellent particle transport.

SLHS Shaft Paddle Mixer Advantages

1. Short Mixing Time: An average mixing cycle for dry mixing can be as follows: filling 20-30 seconds, mixing 40-60 seconds, and discharging 10-20 seconds. This gives a total cycle time of 1.5 – 2 minutes.

2. Lower Production And Maintenance Costs: The benefits of the mechanical fluidizing zone are gentle mixing, no segregation, and a very short mixing time. This gives savings in terms of minimal wear and tear and low energy consumption. Maintenance costs are also very low.

3. Easy Cleaning Of Mixer: Side access doors for entry into the mixer interior can be provided. These also provide access for cleaning the mixer internals after the completion of the batch.

4. Higher Throughput: Because of the short mixing time, this results in savings, both in investment costs and space requirements.

5. Reliable Scale Up: The simple design and mixing principle ensure that lab test results can be reliably scaled up to production levels.

6. Gentle Mixing: Shear is very low, As a result, extremely fragile materials can be mixed with minimal degradation.

|

SUPPLIER PROFILE

|

|||

|---|---|---|---|

| Company: | Henan Herm Machinery Co., Ltd. | ||

| City/State | Zhengzhou, Henan | Country: |

China

|

| Business Type: | Export - Manufacturer / Trading Company | Established: | 2010 |

| Member Since: | 2024 | Contact Person | Merry Zhang |

SUPPLIER PROFILE

City/State/Country -

Zhengzhou, Henan

China

Business Type -

Export - Manufacturer / Trading Company

Established -

2010

Member Since -

2024

Contact Person -

Merry Zhang