Advertisements

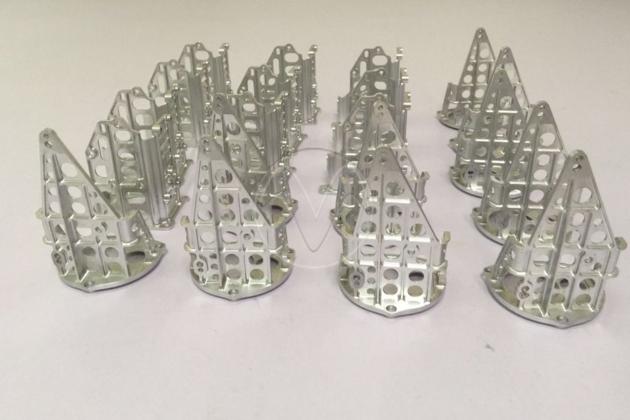

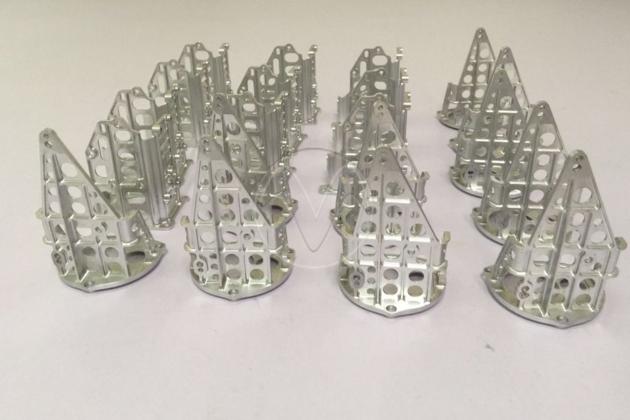

Motorcycle Parts with Metal Injection Molding

| Price: | US$ 1 |

|---|---|

| Minimum Order: | 1 pcs |

| Payment Terms: | 100% payment before delivery |

| Port of Export: |

Product Details

| Model No.: | Brand Name: |

|---|

| Certification: | |

|---|---|

| Specification: | Motorcycle Parts with Metal Injection Molding |

Packaging & Delivery

| Packaging: | as required |

|---|---|

| Delivery/Lead Time: | 1 week |

| Production Capacity: | one million per month |

Product Description

Motorcycle Parts with Metal Injection Molding Motorcycle Parts Mold,Motorcycle Parts Stampings

In the automobile production industry, the body, chassis, fuel tank, radiator plate of the automobile, the steam drum of the boiler, the casing of the container, the iron core silicon steel of the electric motor and the electric appliance are all stamped and processed. There are also a large number of stamping parts in instruments, household appliances, bicycles, office machinery, living utensils and other products.

PRODUCT DESCRIPTION

In the automobile production industry, the body, chassis, fuel tank, radiator plate of the automobile, the steam drum of the boiler, the casing of the container, the iron core silicon steel of the electric motor and the electric appliance are all stamped and processed. There are also a large number of stamping parts in instruments, household appliances, bicycles, office machinery, living utensils and other products.

Compared with castings and forgings, precision stampings are thin, uniform, light and strong. Stamping can produce workpieces with ribs, ribs, undulations or flanging that are difficult to manufacture by other methods to increase their rigidity. Thanks to the use of precision molds, the precision of the workpiece can reach micron level, and the repeatability is high and the specifications are the same, and the holes, bosses and the like can be punched out. The surface and intrinsic properties of stamping sheets have a great influence on the quality of stamped products. Metal stamping processing has the following requirements for stamping materials:

1. The thickness of the stamping material is accurate and uniform;

2, the surface is smooth, no spots, no flaws, no scratches, no surface cracks, etc.;

3. The yield strength is uniform and there is no obvious directionality;

4. High uniform elongation;

5, low yield ratio, work hardenability.

Stamping processing is an efficient production method. It adopts composite molds, especially multi-station progressive molds, which can complete multiple stamping processes on one press to realize unwinding, leveling, punching, forming and finishing of strips. Fully automatic production. High production efficiency, good working conditions, low production costs, and generally can produce hundreds of pieces per minute.

|

SUPPLIER PROFILE

|

|||

|---|---|---|---|

| Company: | Shenzhen Ruitai Mold Technology Co.,Ltd | ||

| City/State | Guangzhou, Guangdong | Country: |

China

|

| Business Type: | Export - Manufacturer / Trading Company | Established: | 2004 |

| Member Since: | 2019 | Contact Person | Emily Ruan |

SUPPLIER PROFILE

City/State/Country -

Guangzhou, Guangdong

China

Business Type -

Export - Manufacturer / Trading Company

Established -

2004

Member Since -

2019

Contact Person -

Emily Ruan